Page 19 (52)

Ver 2_en_2022-06-27

Assembly Instructions

Envistar Flex

4.8

Lifting thermal wheel (1250-D1, 1540-D1) from truck

00192

Follow the instructions for lifting in this manual.

Never exceed the specified weight for the respective lifting method or

lifting equipment.

Never remove or move the factory-fitted lifting lugs.

Use shackle with safety factor 6:1.

Lifting straps must not be pulled through the lifting lugs.

•

•

•

•

•

A falling unit when lifting can cause crushing injuries.

Risk of serious crushing injury.

WARNING!

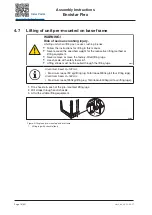

Lifting brackets are placed on different points on the thermal wheel depending on the kind of

lift to be done.

00096

2

1

3

Figure: Lifting of thermal wheel from truck

1. Brackets when lifting from truck

2. Brackets to straighten the thermal wheel to stan-

ding

3. Brackets for lifting the thermal wheel to the unit