VI. TROUBLESHOOTING

101

VI. TROUBLESHOOTING

Troubles

Presumable causes

Remedies

• Filling rate of container is poor

• Front PTO belts are worn down

• Tension of belt is poor

• Net of container is clogged

• Shooter is clogged with grass

• Mower deck is clogged with grass

• Location of cleaning plate is poor

• Too low engine speed

• Engine power is down

• Grass is too moist

• Too tall grass

• Too fast travelling

• Too dense grass

• Adjustment of grass limit sensor is

poor

• Replace belts with new one

• Check belt and correct it

• Clean

• Clear the clogged grass

• Clear the clogged grass

• Set the cleaning plate properly

• Mow at full throttle (

r

)

• Check engine oil, air cleaner, coolant

and clean radiator net, intake net

• Wait until grass becomes dry

• Try to mow two steps

• Slow down sufficiently

• Try to mow two steps

• Adjust it properly

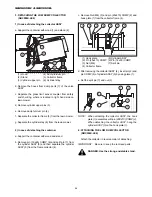

• Excessive noise and vibration

• Loose bolts and nuts

• Fulcrum of collector link is poor

• Cramp of hydraulic hose is loosen

• Short of grease with collector link

• Retighten them properly

• Check and consult your dealer as

necessary

• Cramp it properly

• Inject grease with collector link

• Collector does not move.

• Short of grease with collector link

• Install hydraulic hose by mistake

• Too low engine speed

• Defective hydraulic system

• Inject grease with collector link

• Check and correct

• Raise engine speed

• Consult your dealer

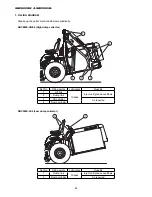

NOISE & VIBRATION

NOISE:

SCMA54

+SBC600X-H

SCMA54

+SBC550X-L

SCMB48

+SBC600X-H

SCMB48

+SBC550X-L

SCMB48

+SBC600X-H

SCMB48

+SBC550X-L

Sound

power

level db(A)

105

105

105

105

105

105

Speed of rotation

Engine min-1(rpm)

2865

2865

2865

2865

2865

2865

Blade min-1(rpm)

1976

1976

2185

2185

2185

2185

Test code

ISO 5349/2631

VIBRATION:

SXG326

SXG323

Weighted root mean square acceleration less than value to which the arms are subjected

Max. 5 m/s2

Max. 5 m/s2

Weighted root mean square acceleration less than value to which the body is subjected

Max. 1.15 m/s2

Max. 1.15 m/s2

Test code

ISO 5349/2631

Summary of Contents for SBC550X

Page 71: ...SXG 70 ...

Page 72: ...XI ELECTRIC WIRING 71 XI ELECTRIC WIRING E TYPE ...

Page 73: ...72 SXG GE TYPE ...

Page 103: ...SBC600XH SBC550XL 102 ...