SFH220,240

114

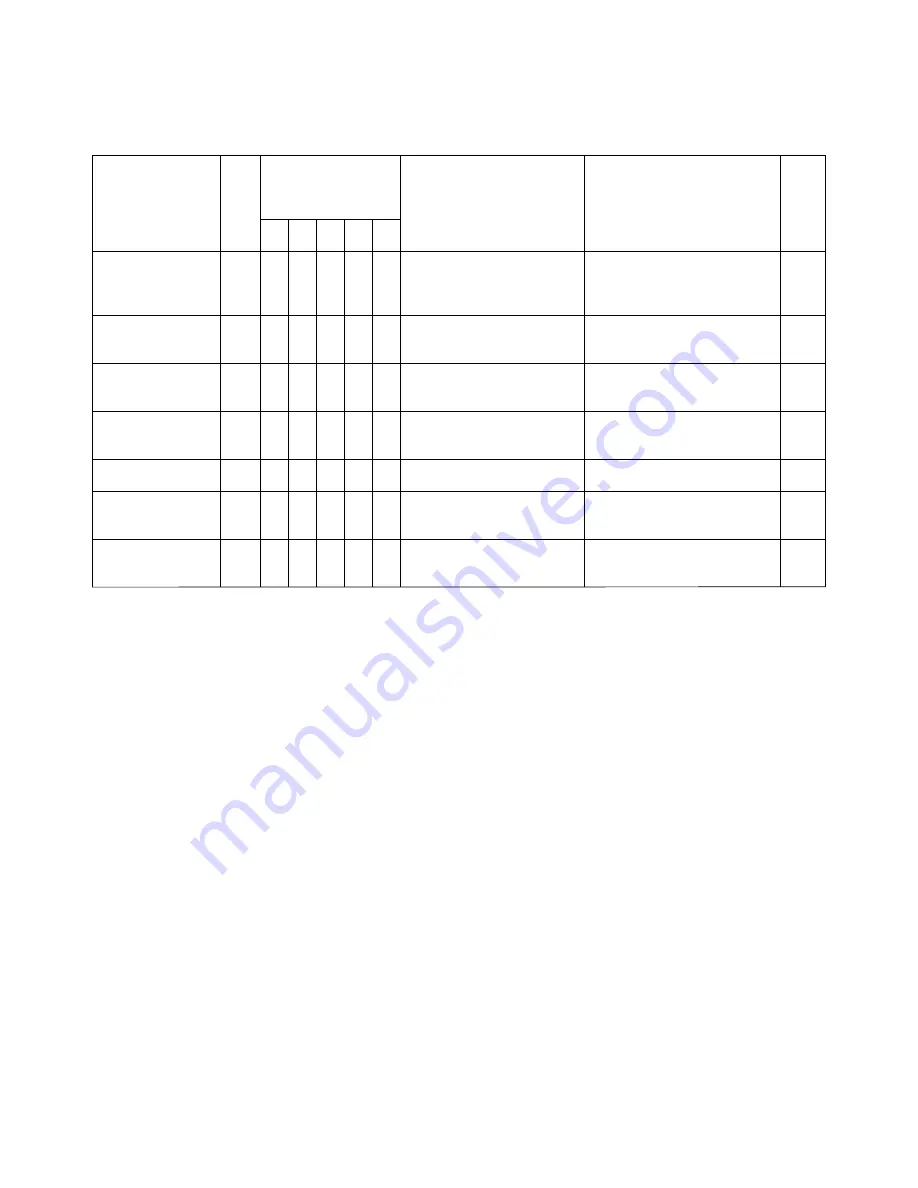

7. PERIODICAL INSPECTION TABLE

IMPORTANT:

・

Above mentioned service intervals should be used as reference criteria. If working conditions are harder, earlier ser-

vice is recommended.

・

When special technology and special tools are required, consult your dealer.

−

Ref.

page

Judgement criteria

Intervals after that

Check points

Inspection and

servicing intervals

(hours of operation)

Pre-

operation

○

50 100 150 200 250

Blade

Bevel gear case

(LH) and (RH)

Inflation of

gauge wheel

Roller and gauge

wheels

Greasing points

Bolls and nuts

Pins and crips

Replace oil after initial 50 h.

and then after every 200 h.

Grease up after every 50 h.

Deformed, broken, worn,

and cracked ones should be

replaced.

Maintain the specified level.

2.1 kgf/cm2

They should turn smoothly.

There should be no loose

ones.

There should be no lost or

deformed ones.

● ○ ○ ○ ●

○

○

○

○

○ ○ ○ ○ ○

99

100

−

98

−

101

○

: Inspection, replenishment, and adjustment

△

: Cleaning and washing

●

: Replacement

★

: Consult your dealer.

Summary of Contents for SBC550FH

Page 1: ...SFH240 SFH220 SCMA48F SCMA54F SMM54F SBC550FL SBC550FH MODELS I S E K I F R O N T M O W E R S ...

Page 33: ...SFH220 240 32 ...

Page 34: ...ISEKI FRONT MOWERS FRONT MOWER SECTION ...

Page 35: ......

Page 92: ...WIRING HARNESS CABLE 91 WIRING HARNESS CABLE Exept G type ...

Page 93: ...SFH220 240 92 G type ...

Page 94: ...ISEKI FRONT MOWERS MOWER DECK SECTION SCMA54F SCMA48F SMM54F SSM54F SFH240F B SFH240F SFH220T ...

Page 95: ......

Page 138: ...ISEKI FRONT MOWERS COLLECTOR SECTION ...

Page 139: ......

Page 150: ...CHAPTER 6 TROUBLESHOOTING 149 ...

Page 151: ...SFH220 240 150 ...