Summary of Contents for 640 - Pentium 4 640 3.2GHz 800MHz 2MB Socket 775 CPU

Page 14: ...Introduction R 14 Thermal Mechanical Design Guide ...

Page 38: ...Thermal Management Logic and Thermal Monitor Feature R 38 Thermal Mechanical Design Guide ...

Page 52: ...Intel Thermal Mechanical Reference Design Information R 52 Thermal Mechanical Design Guide ...

Page 60: ...Acoustic Fan Speed Control R 60 Thermal Mechanical Design Guide ...

Page 72: ...Heatsink Clip Load Metrology R 72 Thermal Mechanical Design Guide ...

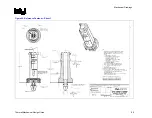

Page 99: ...Mechanical Drawings R Thermal Mechanical Design Guide 99 Figure 50 Reference Fastener Sheet 1 ...

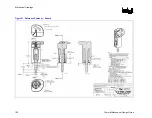

Page 103: ...Mechanical Drawings R Thermal Mechanical Design Guide 103 Figure 54 Clip Heatsink Assembly ...