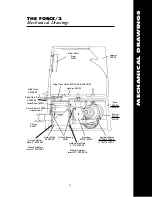

THE FORCE/2

Maintenance, Cont.

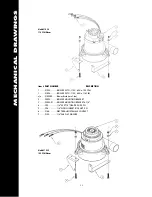

BLOWER MAINTENANCE

Keeping the blower as clean as possible will avoid system overheating.

Overheating will cause lowered production, possible system failure and shorten

the expected life of your FORCE/2. Inspect blower brushes every three

months or 100 hours of use. Replace brushes when they reach

1

⁄

4

inch or less in

length. Change the brushes before the brush stunt touches the commutator.

When reassembling, the lead wires must be isolated from the motor frame and

any rotating parts. For optimum performance, new brushes must be properly

seated against the commutator before operating your FORCE/2 at full power.

NOTE: BRUSH INSTALLATION

After installation of new brushes, plug in machine as normal and set blower

speed control (variable speed) at 30% of full power, run for

1

⁄

2

hour. Set blower

speed control at 70% of full power, run for

1

⁄

2

hour.

CLEANING

Use compressed air to blow out motor and intake of blower every 20-30

hours of use to maximize blower impeller and motor life.

Blower Warranty Considerations.

The following

blower abuse is not covered by warranty:

Damage in shipment

Visible moisture damage such as rust

Rust or other corrosion on motor exterior

Dirty motor or insulation buildup in impeller

Broken components, i.e. brushes, brush holder, etc.

User modification of blower, holes, etc.

User rewound armatures or fields

Evidence of user disassembly

Evidence of foreign object in fan end of motor

M

A

I

N

T

E

N

A

N

C

E

23

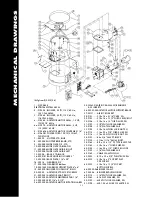

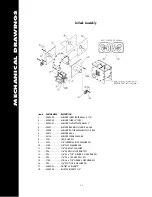

Summary of Contents for FORCE/2 HP

Page 2: ......

Page 4: ...MACHINE INFORMATION 2 ...

Page 46: ...ELECTRICAL DRAWINGS 44 Wiring Diagram Manufactured from 8 02 Present Electrical with GFCI ...

Page 49: ...ELECTRICAL DRAWINGS 47 Wiring Diagram Mfg from 9 02 Present Electrical With Remote Disconnect ...

Page 50: ......

Page 52: ...ELECTRICAL DRAWINGS FORCE 2 Electrical Drawings Cont d ...