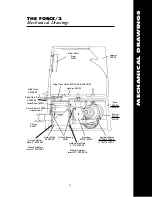

THE FORCE/2

Maintenance, Cont.

REPLACING AIRLOCK SEALS

We recommend changing the airlock seals every 300 hours, 200,000 pounds of

insulation or once a year, whichever comes first.

Unplug the FORCE/2 from electrical power and empty all insulation material

from the hopper. Seal replacement requires a 7/16" socket and ratchet, a 6"

socket extension and a 7/16" open-end wrench. With the machine in an upright

position, locate the seven

1

⁄

4

*

20 bolts holding the seal in place. Loosen and remove

the fasteners. Remove the damaged seal from the rotor shaft. Reverse the process

to install a new seal. Be careful that the direction of the seal is correct. Seal must

be equally wrapped around both sides and seated all the way down on the rotor

shaft! Snug down the bolts. Do not overtighten. Overtightening will cause the

seal to bow out at the ends producing uneven wear and premature failure. To

replace other damaged seals, reconnect electrical power and, using the remote

switch, move the airlock seal into the position for removal. Again, disconnect

from electrical power before doing the actual repair or replacement. Note: Do

not install the seals backwards.

See pages 32 and 33 for additional

illustrations.

M

A

I

N

T

E

N

A

N

C

E

20

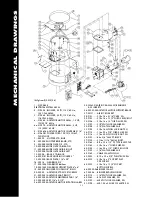

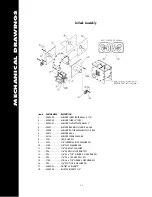

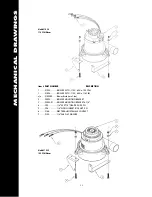

Summary of Contents for FORCE/2 HP

Page 2: ......

Page 4: ...MACHINE INFORMATION 2 ...

Page 46: ...ELECTRICAL DRAWINGS 44 Wiring Diagram Manufactured from 8 02 Present Electrical with GFCI ...

Page 49: ...ELECTRICAL DRAWINGS 47 Wiring Diagram Mfg from 9 02 Present Electrical With Remote Disconnect ...

Page 50: ......

Page 52: ...ELECTRICAL DRAWINGS FORCE 2 Electrical Drawings Cont d ...