8

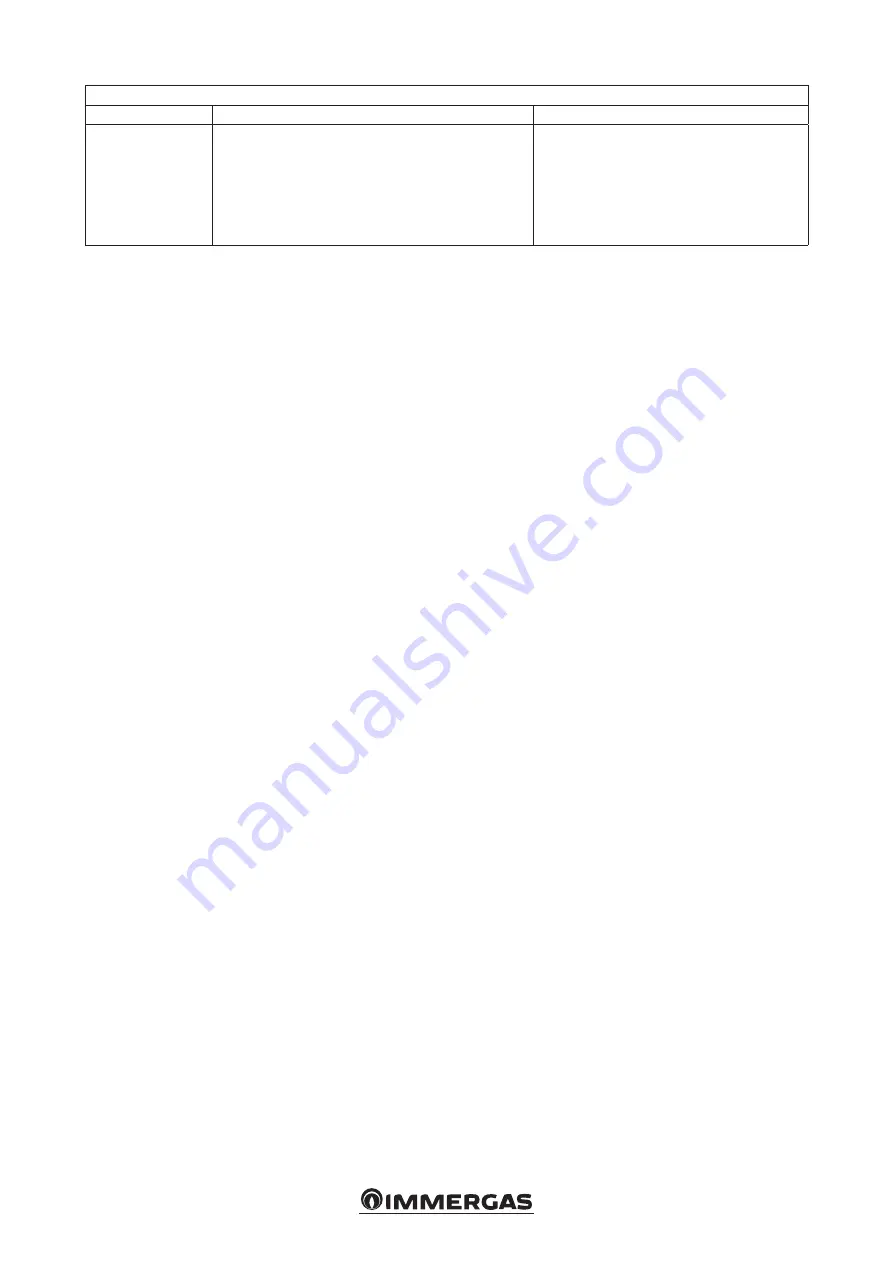

Menù Service ->Test switch Max pres

Menu item

Description

Range

Test Pressure switch

Test method for high pressure switch.

N.B. to run the test, set the value to 1 and wait for the test result

0 = Off

1 = Test required

N.B. the following states are managed by the machine DO NOT USE

2 = AP Test in progress

3 = AP Test performed correctly

4 = AP Test failed for maximum time reached

5 = AP Test failed for flow switch error

6 = AP Test failed for low water temperature

7 = AP Test failed for inverter error

N.B.: the Test mode has been implemented for

the execution of tests. When the Test mode

is active, the water temperature set point is

ignored by the control system.

When the Test mode is active, the pump

operation is forced.

Attention: if the test shows the need to replace

the pressure switch, you must recover the

coolant charge, this type of pressure switch is

not installed on automatic valves (Schrader

type).

Visually inspect the protection tools (valves,

pressure switches), at least once a year.

If the chiller works in a place where the

atmosphere is corrosive, the protective device

must be inspected more frequently.

Periodically search for leaks, immediately

eliminating all those eventually found.

Periodically ascertain that the vibration level is

contained within the standard limits, meaning

that it is close to that emitted at the time of first

chiller start-up.

Before opening a cooling circuit, make sure to

transfer the coolant in the cylinders specifically

designed for this purpose and consult the

pressure gauges.

Following the failure of equipment, replace the

coolant observing the procedure described in

NF E29-795 or have the coolant analysed by a

specialised laboratory.

If the cooling circuit remains open after

an intervention (i.e. the replacement of a

component, etc.):

•

seal the openings if duration is less than one

day;

•

if longer than 1 days, charge the circuit

with nitrogen without oxygen (principle of

inertia).

The purpose is to prevent the penetration of

atmospheric humidity and resulting corrosion.

1.2.4. Considerations about the safety of

repair interventions.

The maintenance of all installation components

must be performed by authorised personnel,

in order to prevent the risk of deterioration

and injuries. Promptly eliminate any defects

and leaks. The authorised technician is obliged

to promptly repair the fault detected. After

repairing the individual units, make sure that the

protection devices work properly and fill out a

verification report of the parameters.

Observe the rules and recommendations

prescribed for the unit, as well as the safety

standards of the HVAC systems, such as: EN

378, ISO 5149, etc.

If the power supply cable is damaged, it

must be replaced by the manufacturer, its

assistance service or personnel with similar

requirements, in order to avoid the arising of

a potentially dangerous situation.

RISK OF EXPLOSION.

When purging and pressurising the cooling

circuit required for leak detection, do not use

either air or gas containing oxygen. Mixtures

of pressurised air or gases containing oxygen

can cause explosions. The oxygen triggers a

violent reaction if it comes into contact with

oils and lubricants.

Therefore, for leak detection, it is essential to

use only nitrogen, possibly supplemented with

suitable gas tracer.

Failure to comply with these recommendations

could imply serious consequences, even fatal,

for people, as well as serious damage to the

system.

Never exceed the maximum operating

pressures specified. Check the minimum and

maximum test pressures allowed, comparing

them with that indicated on this manual and

with the pressures indicated on the unit plate.

Do not unsolder or cut with cutting torch

the coolant pipes or any cooling circuit

components before all the coolant (liquid

and vapour) and oil have been made to flow

through the heat pump. The steam traces must

be expelled from the circuit by blowing dry

nitrogen. If in contact with an open flame, the

coolant generates toxic gases.

For this reason it is necessary to have the

required protection means and have a flame

extinguishing system at hand which is suitable

to the appliance features and type of coolant

used in it.

The coolant must never be decanted for

siphoning.

Prevent the liquid coolant from coming into

contact with the skin or sprayed in the eyes.

Wear protective gloves and goggles. If the

coolant falls on the skin, was it off with

abundant water and soap. If the coolant is

sprayed in the eyes, immediately rinse them

with running water and then immediately

consult a doctor.

The accidental release of coolant, caused by

minor leaks or significant leaks following

the rupture of a pipe or sudden leak from

a discharge valve, can cause frostbite and

burns to exposed personnel. Do not ignore

such injuries. Installers, owners and skilled

technicians of the assistance service of these

units must:

•

Contact a doctor before treating these

injuries.

•

Have access to a first aid kit, especially to treat

eye injury.

We recommend observing the provisions of EN

378-3 Appendix 3 and ISO5149.

Never use open flames or live steam on the

cooling circuit. Otherwise, dangerous pressure

may develop inside them.

Summary of Contents for AUDAX TOP

Page 1: ...AUDAX TOP 18 21 ErP IE Instruction and recommendation booklet 1 040572ENG...

Page 2: ......

Page 70: ......

Page 71: ......