35

important that the airflow is not reduced

to maximize system performance and

life. Always verify that the systems

airflow is not impaired by the filtering

system that has been installed, by

performing a temperature rise and

temperature drop test.

Keep the air filters clean at all times.

Vacuum dirt from filter, wash with

detergent and water, air dry thoroughly

and reinstall.

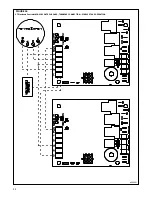

See Table 8 and Figures 24, 25, 26, and

27 for proper filter sizes and locations.

1. 14”- 50,000 BTUH unit requires

removal of 3

1

/

2

” segment of filter and

frame to get proper width for a bottom

filter.

2. 21”-100,000 BTUH unit requires

removal of 3

1

/

2

” segment of filter and

frame to get proper width for a side

filter.

3. 24

1

/

2

”-125,000 and 150,000 BTUH

units require removal of 7” segment of

filter and frame to get proper width for

a side filter.

IMPORTANT:

Do not operate the

system without filters. A portion of the

dust entrained in the air may temporarily

lodge in the air duct runs and at the

supply registers. Any recirculated dust

particles will be heated and charred by

contact with the furnace heat

exchanger. This residue will soil

ceilings, walls, drapes, carpets, and

other household articles.

SYSTEM OPERATION

INFORMATION

Advise The Customer To:

1. Keep the air filters clean. The heating

system will operate better, more

efficiently and more economically.

2. Arrange the furniture and drapes so

that the supply air registers and the

return air grilles are unobstructed.

3. Close doors and windows. This will

reduce the heating load on the

system.

4. Avoid excessive use of kitchen &

bathroom exhaust fans.

5. Do not permit the heat generated by

television, lamps or radios to

influence the thermostat operation.

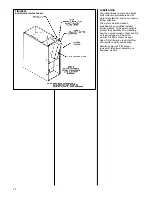

6 Except for the mounting platform,

keep all combustible articles three

feet from the furnace and vent

system.

7.

IMPORTANT:

Replace all blower

doors and compartment covers after

servicing the furnace. Do not operate

the unit without all panels and doors

securely in place.

8. Proper operation of the system with

constant air circulation.

COMBUSTIBLE MATERIAL MUST

NOT BE PLACED ON OR AGAINST

THE FURNACE JACKET OR WITHIN

THE SPECIFIED CLEARANCES OF

THE VENT PIPE. THE AREA

AROUND THE FURNACE MUST BE

KEPT CLEAR AND FREE OF ALL

COMBUSTIBLE MATERIALS

INCLUDING GASOLINE AND OTHER

FLAMMABLE VAPORS AND

LIQUIDS. PLACEMENT OF

COMBUSTIBLE MATERIALS ON,

AGAINST OR AROUND THE

FURNACE JACKET CAN CAUSE AN

EXPLOSION OR FIRE RESULTING

IN PROPERTY DAMAGE,

PERSONAL INJURY OR DEATH.

THE FURNACE OWNER SHOULD BE

CAUTIONED THAT THE FURNACE

AREA MUST NOT BE USED AS A

BROOM CLOSET OR FOR ANY

OTHER STORAGE PURPOSES.

ANNUAL INSPECTION

The furnace should operate for many

years without excessive scale build-up

in the flue passageways, however, it is

recommended that a qualified installer,

service agency, or the gas supplier

actually inspect the flue passageways,

the vent system and the main and pilot

burners for continued safe operation

paying particular attention to

deterioration from corrosion or other

sources.

HOLES IN THE VENT PIPE OR HEAT

EXCHANGER CAN CAUSE TOXIC

FUMES TO ENTER THE HOME

RESULTING IN CARBON

MONOXIDE POISONING OR DEATH.

THE VENT PIPE OR HEAT

EXCHANGER MUST BE REPLACED

IF THEY LEAK.

• IMPORTANT:

It is recommended

that at the beginning of the heating

season and approximately midway

in the heating season a visual

inspection be made of the main

burner flames and pilot flame on

standing pilot models for the desired

flame appearance by a qualified

installer, service agency, or the gas

supplier.

• IMPORTANT:

It is also

recommended that at the beginning

of the heating season, the flame

sensor on hot surface ignition

models be cleaned with steel wool

by a qualified installer, service

agency, or the gas supplier.

•

IMPORTANT:

It is recommended

that an annual inspection and

cleaning of all furnace markings be

made to assure legibility. Attach a

replacement marking, which can be

obtained through the distributor, if

any are found to be illegible or

missing.

IMPORTANT: FOR Nox MODELS –

At the beginning of the heating season

a visual inspection of the Nox device

should be made to ensure they have

not become obstructed by insects

nests or anything else which may

effect performance.

REPLACEMENT PARTS

Contact your local distributor for a

complete parts list. See enclosed

sheet.

TROUBLESHOOTING

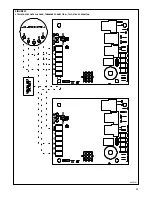

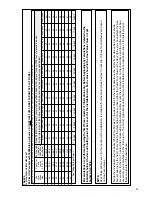

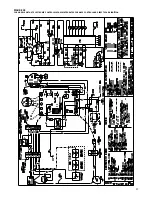

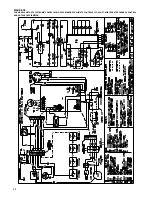

Refer to Figure 28 for determining

cause of unit problems.

WIRING DIAGRAM

Figures 29 and 30 are complete wiring

diagrams for the furnace and power

sources.

WARNING

!

WARNING

!