29

AIR FLOW

The importance of proper air flow over

the heat exchanger cannot be over

emphasized.

IT IS IMPORTANT THAT EACH

DUCT SYSTEM BE SIZED AND

INSTALLED FOR THE SPECIFIC

APPLICATION BY PROPERLY

APPLYING THE APPROPRIATE

INDUSTRY ACCEPTED STANDARD.

IF LESS THAN MINIMUM

STANDARDS ARE APPLIED, THE

EQUIPMENT USER COULD EXPECT

TO EXPERIENCE HIGHER UTILITY

BILLS, MAJOR COMPONENT

FAILURE, VARYING DEGREES OF

AIR NOISE OR OTHER

UNSATISFACTORY ISSUES, OVER

WHICH THE MANUFACTURER HAS

NO CONTROL.

TEMPERATURE RISE CHECK

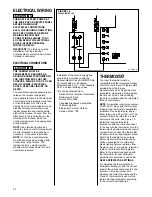

To determine if the air flow is correct,

make a temperature rise check.

1. Insert a thermometer in the supply

air duct as close to the furnace as

possible yet out of a direct line

from the heat exchanger. See

Figure 21.

2. Insert a thermometer in the return

air duct as close to the furnace as

possible.

FIGURE 21

TEMPERATURE RISE MEASUREMENT

GAS FURNACE (DIRECT

DRIVE) INSTRUCTIONS FOR

CHANGING BLOWER SPEED

DISCONNECT THE ELECTRICAL

SUPPLY TO THE FURNACE BEFORE

ATTEMPTING TO CHANGE THE

BLOWER SPEED. FAILURE TO DO

SO CAN CAUSE ELECTRICAL

SHOCK RESULTING IN SEVERE

PERSONAL INJURY OR DEATH.

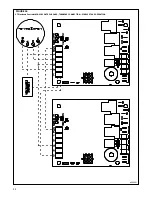

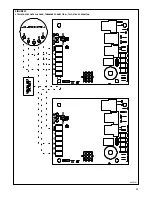

The blower motor is wired for blower

speeds required for normal operation

as shown.

If additional blower speed taps are

available (leads connected to “M1” and

“M2” on the electronic control), speeds

may be changed if necessary to fit

requirements of the particular

installation. Reconnect the unused

motor leads to “M1” or “M2.” Check

motor lead color for speed designation.

Heating speeds should not be reduced

where it could cause the furnace air

temperature to rise to exceed the

maximum outlet air temperature

specified for the unit.

IMPORTANT:

Always check air

temperature rise after changing the

heating speed for any reason.

WARNING

!

!

CAUTION

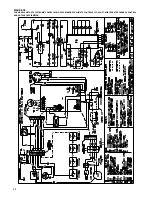

FIGURE 22

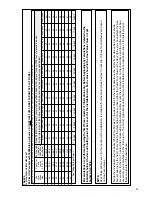

TYPICAL FURNACE NAME PLATE