31

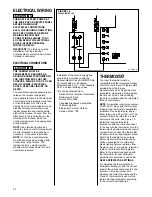

SAFETY FEATURES

LIMIT CONTROL

The high limit cut-off temperature is set

at the factory and cannot be adjusted.

The temperature setting prevents the

air temperature leaving the furnace

from exceeding the maximum outlet air

temperature, which, if exceeded, will

shut the furnace down.

There are several reasons for a limit

switch to open and almost always

involve low airflow through the furnace.

1. A dirty or restricted air filter.

2. A dirty or restricted cooling coil.

3. Undersized or restricted return air

system.

4. Undersized or restricted supply air

system.

5. A problem affecting the main

blower:

A. A wrong speed tap selection.

B. Failing motor bearings.

C. Low voltage to the motor.

D. Dirty blower wheel.

E. Wrong motor rotation.

F. Blower wheel slipping on the

F.

motor shaft.

6. Overfiring the furnace with too much

gas pressure.

7. Ventilation problems.

FLAME ROLL-OUT

SAFETY SWITCHES

Furnaces are equipped with safety

switches to protect against flame roll-

out conditions in the burner

compartment, which, if tripped, will

terminate the heating cycle. In the

event of a flame roll-out condition, the

switch will shut the furnace down. If a

switch is tripped, it must be manually

reset. DO NOT jumper or reset this

switch. If this switch should trip, a

qualified installer, service agency or

the gas supplier should be called to

diagnose and/or correct the source of

tripping. If this unit is mounted in a

closet, the door must be closed when

making this check.

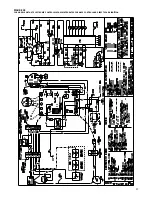

PRESSURE SWITCH

This furnace is equipped with a

normally-open pressure switch that

monitors pressure conditions within the

furnace vent system during the heating

cycle.

There are several reasons for the

pressure switch not to close.

1. An inoperative induced draft blower.

2. A loose or leaky pressure switch

hose.

3. A blockage in the vent.

4. Severe downdrafts canceling the

draft from the inducer fan.

5. A leaky gasket at the induced draft

blower.

6. Improperly sized or installed vent.

The pressure switch contacts must

open before the unit can go through

another heating cycle.

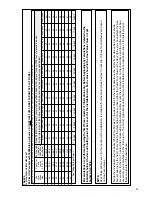

See troubleshooting chart in this book

for troubleshooting recommendations.

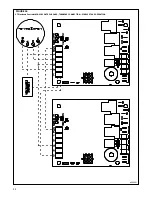

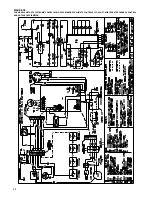

3. Operate the furnace.

4. When the thermometer in the

supply air duct stops rising

(approximately five minutes),

subtract the return air temperature

from the supply air temperature.

The difference is the temperature

rise.

5. Compare the measured

temperature rise to the approved

temperature rise range listed on

the furnace name plate. See

Figure 22.

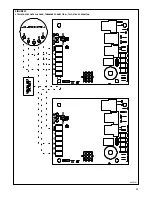

If the measured temperature rise is

above the approved range, the air flow

is too low. More air must be moved by

speeding up the blower, by removing

restrictions in the duct system, or by

adding more supply or return air duct. If

the measured temperature rise is below

the approved range, the air flow is too

much. Use lower speed tap on the

multi-speed blower.

Ideally the measured temperature rise

should be in the middle of the range.

IMPORTANT:

Some high-efficiency

filters have a greater than normal

resistance to airflow. This can

adversely affect furnace operation. BE

SURE TO CHECK AIRFLOW if using

any filter other than factory-provided

filter.