13

GENERAL INFORMATION

The furnace must be vented in

accordance with these instructions,

National Fuel Gas Code, ANSI Z223.1

and/or the Natural Gas Installation

Code, CSA-B149.1 & .2 and

requirements or codes of the local utility

or other authority having jurisdiction.

DEVICES ATTACHED TO THE FLUE

OR VENT FOR THE PURPOSE OF

REDUCING HEAT LOSS UP THE

CHIMNEY HAVE NOT BEEN TESTED

AND HAVE NOT BEEN INCLUDED IN

THE DESIGN CERTIFICATION OF

THIS FURNACE. WE, THE

MANUFACTURER, CANNOT AND

WILL NOT BE RESPONSIBLE FOR

INJURY OR DAMAGE CAUSED BY

THE USE OF SUCH UNTESTED

AND/OR UNCERTIFIED DEVICES,

ACCESSORIES OR COMPONENTS.

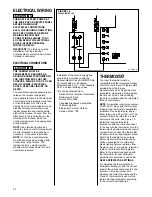

DRAFT INDUCER

VENT PIPE ATTACHING HOLES

MUST BE PREDRILLED IN THE

DRAFT INDUCER COLLAR TO

PREVENT DAMAGING THE

INDUCER. DRILL 1/8

”

DIAMETER

HOLES THROUGH THE VENT PIPE

AND COLLAR AND USE #8 SCREWS

TO ATTACH. SEE FIGURE 9.

FAILURE TO FOLLOW THIS

WARNING CAN CAUSE

RECIRCULATION OF FLUE

PRODUCTS CAUSING CARBON

MONOXIDE POISONING

RESULTING IN PERSONAL INJURY

OR DEATH.

IMPORTANT APPLICATION

NOTES

When the furnace is used as a

replacement, the existing vent system

should be inspected to assure that

there are no obstructions, blockage, or

any signs of corrosion.

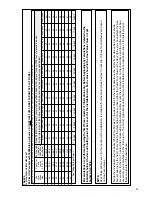

NOTE: WHEN THE VENT TABLE

PERMITS MORE THAN ONE

DIAMETER OF PIPE FOR A

CONNECTOR OR VENT, THE

SMALLEST PERMITTED DIAMETER

MUST BE USED,

VENT PIPE MAY BE TYPE “B-1,”

EITHER RIGID OR SUITABLE

FLEXIBLE CONSTRUCTION THAT

CARRIES A U.L. LISTING.

COMMON VENTING IS ALLOWED

WITH VERTICAL B-1 VENT

SYSTEMS, AND LINED MASONRY

CHIMNEYS. FOLLOW THE

NATIONAL FUEL GAS CODE, ANSI

Z223.1 AND/OR THE NATURAL GAS

INSTALLATION CODE, CSA-B149.1 &

.2 FOR PROPER INSTALLATION

PRACTICES.

SINGLE WALL VENT CONNECTORS

TO “B-1 VENT OR MASONRY

CHIMNEYS” MAY BE USED UNDER

THE GUIDELINES OF THE

NATIONAL FUEL GAS CODE, ANSI

Z223.1 AND/OR THE NATURAL GAS

INSTALLATION CODE,

CSA-B149.1 & .2.

The entire length of the vent

connector shall be readily

accessible for inspection, cleaning

and replacement.

WARNING

!

WARNING

!

FURNACE CATEGORY

INFORMATION

This furnace is shipped as a Category

I

type induced draft furnace. A Category

I

furnace operates with a nonpositive

vent pressure and has a vent gas

temperature at least 140°F above the

dew point of the vent gases. A

Category

I

type may be a draft hood

equipped furnace or have a fan

assisted combustion system (induced

draft). The inducer is used to pull flue

products through the combustion

chamber and as they leave the

furnace, most of the energy has been

dissipated. The buoyant effect of the

flue gases provides venting to the

outdoors.

During the off cycle, the inducer is off

and there is very little flow through the

vent, cooling the vent. During the on

cycle there is no dilution airflow, as

with a draft hood type furnace.

Although the vent heats up rapidly

without dilution air, the flue products

contain more water vapor, which

results in a higher dew point

temperature. It is most

important

that

you follow the guidelines in these

instructions to prevent the possible

formation of condensation in the

venting system.

As a Category

I

furnace it may be

vented vertically with type B-1 vent

pipe and also may be common vented,

as described in these instructions.

FIGURE 9

ATTACHING TO DRAFT INDUCER COLLAR

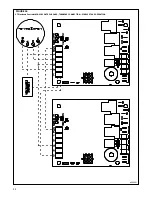

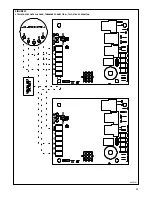

VENTING

AO991-01

VENT PIPE

ADAPTER

CONNECTOR*

*SEE PAGE 14

VERTICAL VENTING