27

LIGHTING INSTRUCTIONS

This appliance is equipped with either a

direct spark ignition device or a hot

surface silicon carbide ignition device.

This device lights the main burners each

time the room thermostat (closes) calls for

heat. See lighting instructions on the

furnace.

TO START FURNACE

1.

BE SURE THAT THE MANUAL GAS

CONTROL HAS BEEN IN THE “OFF”

POSITION FOR AT LEAST FIVE

MINUTES. DO NOT ATTEMPT TO

MANUALLY LIGHT THE MAIN

BURNERS. FAILURE TO FOLLOW

THIS WARNING CAN CAUSE A

FIRE OR AN EXPLOSION

RESULTING IN PROPERTY

DAMAGE, PERSONAL INJURY OR

DEATH.

2. Set the thermostat to lowest setting.

3. Turn off all electric power to the

appliance.

4. This appliance does not have a pilot.

It is equipped with an ignition device

which automatically lights the burner.

Do NOT try to light the burner by hand.

5. Remove control door.

6. Move switch to the "OFF" position.

NOTE:

Use only your hand to move

the gas control switch. Never use

tools. If the switch will not move by

hand, don't try to repair it; call a

qualified service technician. Force

or attempted repair may result in a

fire or explosion.

7. Wait five (5) minutes to clear out any

gas. Then smell for gas, including

near the floor. If you smell gas, STOP!

Follow the safety instructions on the

front page of this manual. If you don't

smell gas, go to the next step.

8. Move switch from "OFF" position to

"ON" position.

9. Replace control door.

10. Turn on all electric power to the

appliance.

11. Set the thermostat to desired setting.

12. If the appliance will not operate, follow

the instructions below to shut down

furnace and call your service

technician or gas supplier.

TO TURN OFF GAS TO FURNACE

1. Set the thermostat to the lowest setting.

2. Turn off all electric power to the

appliance if service is to be performed.

3. Remove control door.

4. Move switch to the "OFF" position.

5. Replace control door.

WARNING

!

SHOULD OVERHEATING OCCUR OR

THE GAS SUPPLY FAIL TO SHUT

OFF, SHUT OFF THE MANUAL GAS

VALVE TO THE APPLIANCE BEFORE

SHUTTING OFF THE ELECTRICAL

SUPPLY. FAILURE TO DO SO CAN

CAUSE AN EXPLOSION OR FIRE

RESULTING IN PROPERTY DAMAGE,

PERSONAL INJURY OR DEATH.

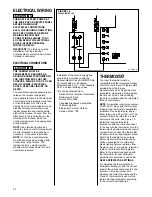

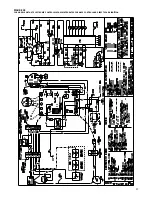

SEQUENCE OF OPERATION

UT ELECTRONIC CONTROLS &

INVESYS CLIMATE CONTROLS

Integrated Controls with Hot

Surface Ignition.

1. Each time the thermostat “W”

(Heating) contacts close, the

induced draft blower (inducer)

begins a prepurge cycle.

2. The air proving negative pressure

switch(es) closes.

3.

5 seconds after the pressure

switch(es) close, the hot surface

igniter begins heating for 30

seconds

to full temperature. The

induced draft blower operates for

the complete heating cycle.

4. After the 30-second igniter warm

up,

the gas valve opens for an

8-second trial for ignition.

5. The igniter lights the gas burners

and

stays energized for the first

7 seconds after the gas valve

opens.

6. 8 seconds after the gas valve

opens

the remote flame sensor

must prove flame ignition for one

second

using the process of flame

rectification. If the burners don’t

light, the system goes through

another ignition sequence. It does

this

up to

four

times.

7. The main blower starts

approximately 20 seconds after the

burners ignite.

8. When the thermostat “W” (Heat

Call) ends, the gas valve closes,

the burners go out, the induced

draft blower stops after

a 10-

second post-purge,

and the

negative pressure switch(es) open.

9. The main blower continues until

timed off by the setting on the

integrated furnace control board.

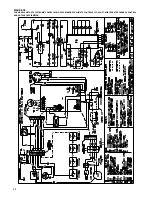

Sequence if the system doesn’t light

or doesn’t sense flame:

1. On a call for heat, the control runs

the inducer for 35 seconds to

prepurge.

2. 5 seconds into prepurge, the hot

surface igniter heats for 30

seconds. The inducer continues to

run.

3. After the 30-second igniter warm

up, the gas valve opens for an

8-second trial for ignition. The

inducer continues and the igniter

stays energized.

4. If flame is not sensed during the

8th second after the gas valve

opens, the gas valve closes, and

the igniter de-energizes.

5. After a 10-second post-purge, the

inducer stops and the control

verifies that the pressure switch

has opened. Once the open

pressure switch is confirmed, the

control begins the next ignition

cycle by energizing the inducer for

a pre-purge of 30 seconds. After

the 30-second pre-purge, the

igniter energizes and begins a 30-

second warm-up period (inducer is

still running). After a 30-second

igniter warm-up period (60 sec. of

ind. running), the gas valve opens

and the control looks for a flame

signal for up to 8 seconds. If no

flame is sensed, the control goes

into “self-healing” mode, in which

the blower and inducer both run for

three minutes before another

ignition attempt is made.

NOTE: The following applies only

to units manufactured before

third Quarter 2003:

After 5-second

inter-purge, the control begins a

30-second pre-purge followed by a

30-second igniter warm-up period

(inducer is still running). After the

30-second igniter warm-up period,

the gas valve opens and the

control looks for a flame signal for

up to 8 seconds. If no flame is

sensed, the control goes into “self-

healing” mode, in which the blower

and inducer both run for three

minutes before another ignition

attempt is made.

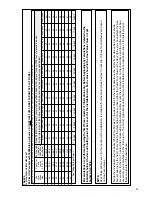

6. The control attempts to ignite up to

four times (first attempt followed by

three retries). After the fourth

failure to ignite, the control goes

into a one-hour “soft-lockout,”

during which the control will not

respond to the thermostat heat call

(W). The lockout can be reset by

shutting off main power to the

furnace for five seconds, or by

turning the heat call (W) from the

thermostat off and then back on.

Note that second and fourth

ignition attempts will have a 30-

second pre-purge followed by a 30-

second igniter warm-up period.

This prevents the igniter from

overheating.

7. The above sequence will repeat

after a one hour delay. It will

continue repeating until ignition is

successful or the call for heat is

terminated.

8.

To reset the lock out, make and

break power either at the

thermostat or at the unit

disconnect switch for 5 to 10

seconds.

It then goes through

another set of trials for ignition.

UT Electronic Controls Direct Spark

Ignition

WARNING

!

START-UP PROCEDURE