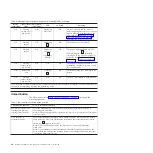

External tape drive specifications

The following sections show the physical, power, and environmental specifications

for the external tape drive. For specifications for the internal tape drive, see

“Internal tape drive specifications.” Specifications for tape cartridges are shown in

“Environmental specifications.”

Physical specifications

Width

213 mm (8.4 in.)

Length

332 mm (13.1 in.)

Height

58 mm (2.3 in.)

Weight (without a cartridge)

4.3 kg (9.4 lbs.)

Power specifications

AC line current

100 to 240 Vac

Line frequency

50 to 60 Hz, auto-ranging

Line current at 100 Vac

0.48 A

Line current at 240 Vac

0.20 A

Other specifications

Maximum altitude for operating and storage

3,048 m (10,000 ft)

Maximum altitude for shipping

12,192 m (40,000 ft)

Environmental specifications

Environmental factor

Operating

Storage or Shipping

Drive temperature

10 to 40°C (50 to 104°F)

-40 to 60°C (-40 to 140°F)

Relative humidity (noncondensing)

20 to 80%

10 to 90%

Wet bulb temperature (maximum)

26°C (78.8°F)

26°C (78.8°F)

Internal tape drive specifications

The following sections show the physical, power, and environmental specifications

for the internal tape drive. For specifications for the external tape drive, see

“External tape drive specifications.” Specifications for tape cartridges are shown in

“Environmental specifications” on page 8.

Physical specifications

Without bezel

With bezel

Width

146 mm (5.7 in.)

148 mm (5.8 in.)

Length

205 mm (8.1 in.)

210 mm (8.3 in.)

Height

41 (1.6 in.)

42.7 mm (1.7 in.)

Weight (without a cartridge)

1.61 kg (3.5 lbs.)

Chapter 1. Product description

7

Summary of Contents for L5X

Page 2: ......

Page 10: ...viii Half High LTO Gen 5 SAS Tape Drive Installation and User s Guide...

Page 14: ...xii Half High LTO Gen 5 SAS Tape Drive Installation and User s Guide...

Page 16: ...xiv Half High LTO Gen 5 SAS Tape Drive Installation and User s Guide...

Page 58: ...40 Half High LTO Gen 5 SAS Tape Drive Installation and User s Guide...

Page 71: ...Figure 14 RID tag on rear panel Chapter 5 Resolving problems 53...

Page 72: ...54 Half High LTO Gen 5 SAS Tape Drive Installation and User s Guide...

Page 76: ...58 Half High LTO Gen 5 SAS Tape Drive Installation and User s Guide...

Page 90: ...72 Half High LTO Gen 5 SAS Tape Drive Installation and User s Guide...

Page 102: ...84 Half High LTO Gen 5 SAS Tape Drive Installation and User s Guide...

Page 119: ......

Page 120: ...Part Number 60Y1487 Printed in USA 1P P N 60Y1487...