7.0 Maintenance

_________________________________________________________________________________________

CC1132751D 17

7.0 Maintenance

WARNING !

SERVICING MUST ONLY BE CARRIED-OUT BY

TRAINED SERVICE ENGINEERS COMPETENT IN THE

MAINTENANCE, MAINS ELECTRICAL SUPPLY AND

STARTER EQUIPMENT

7.1 Routine Service

The work listed must be carried-out at the indicated running

hours, which must be regarded as a maximum. In dusty, hot or

humid conditions, more frequent servicing may be necessary.

On RS units after long periods, speed control unit capacitors and

cooling fan(s) should be replaced to ensure reliability of the unit.

7.2 Service Kits

If you are unable to carry-out the work safely in the required

manner, your Hydrovane Distributor will be pleased to help.

Use genuine parts and approved oils during routine servicing,

the following service kits are available:

Oil change kit, 2000 hour/12 months, use KOHR457.

Maintenance kit, 4000 hour/2 year, use KMHR457 or

KMHR457LS. Serial numbers: HR04-000210-1605, HR05-

000445-1605 & HR07-000790-1601.

Full overhaul/top-up kit, 20000 hour/10 year, use KTHR4,

KTHR5, KTHR7 (inc. KWHR457) use with KMHR kit.

Additional kits available for full product support are as follows:

Solenoid valve kit, 8000 hour/4 year, use KSVDOLHR457,

KSVSDHR457.

Contactor kit, non-scheduled item, use KCHR457DOL,

KCHR457RS, KCHR457SD

Electrical kit, 20000 hour/10 year, use KEHR457DOL,

KEHR457RS, KEHR457SD

Oil Seal and Wear sleeve kit, 20000 hour/10 year, use

KWHR457 (Inc in KT KIT).

Motor bearing kit (HEBEI Motor), 20000 hour/10 year, use

KBH132 (HR04), KBV132 (HR05/07)

7.3 Service Instructions

WARNING !

STOP THE COMPRESSOR AND ISOLATE FROM THE

MAINS ELECTRICAL SUPPLY. LOCK THE ISOLATOR

IN THE OFF POSITION. FIT A SAFETY NOTICE

ADVISING THAT WORK IS BEING CARRIED OUT ON

THE COMPRESSOR.

CLOSE THE AIR OUTLET VALVE TO ISOLATE THE

COMPRESSOR FROM THE AIRLINE SYSTEM. FIT A

SAFETY NOTICE ADVISING THAT IT IS NOT TO BE

OPENED.

DO NOT PROCEED UNTIL THE AIR PRESSURE

GAUGE READS ZERO !

AVOID UNNECESSARY CONTACT WITH HOT OIL

AND

COMPONENTS.

GLOVES

ARE

RECOMMENDED IF DRAINING OIL WHEN THE

COMPRESSOR IS HOT!

7.4 Panel Removal

Unlock and open the hinged front door panel to allow removal of

the top panel. Remove any fixing screws and pull the top panel

from the location slots and lift clear of the compressor.

7.5 Oil Filling/Draining (Fig.7.1)

Remove filler plug (A) with bonded seal (B), remove and retain

the level plug (C).

Place a suitable container below the oil drain point, remove drain

plug (D) with bonded seal (E) and allow oil to drain.

When draining is complete, replace the drain plug and clean

away any oil spillages.

Fill with approved oil to overflow from the level plug. Stop filling,

replace the level and filler plugs, and clean away any spillage.

If the oil filter has been replaced, run the compressor for a short

time (30 seconds) and re-check the oil level.

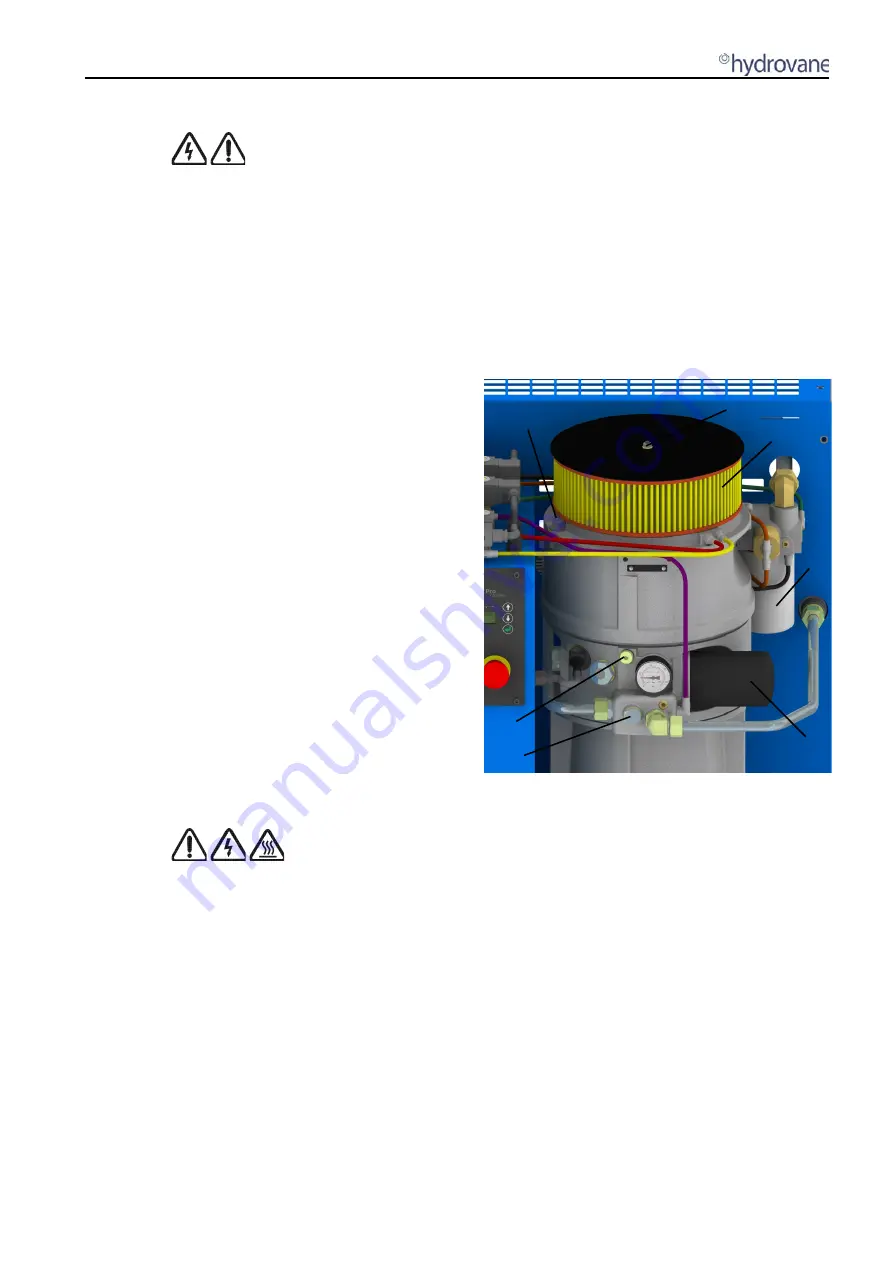

Fig 7.1 Filler Plug, Air Filter, Separator, Oil Drain

and Filter

7.6 Oil Filter (Fig 7.1)

Unscrew oil filter (F) anti-clockwise, minimise spillage from the

canister and discard in a safe manner.

Using a new filter, smear a small amount of oil onto the seal,

screw in clockwise, hand tight only.

7.7 Air Filter (Fig.7.1)

Remove M6 Nut (G) with bonded seal (H), remove the cover

plate. Lift off the air filter element (J) and discard in a safe

manner.

Using a new air filter element, replace over filter support and fix

the cover plate back on with, nut and bonded seal.

7.8 Oil Separator (Fig.7.1)

Unscrew oil separator (K) anti-clockwise and discard in a safe

manner.

Using a new separator, smear a small amount of oil onto the

seal, screw clockwise, hand tight only.

A B

C

D E

F

K

G H

J

Summary of Contents for HR04

Page 1: ...HR04 HR07 Models User Handbook Original Instructions CC1132751D 10 2018 GB...

Page 2: ......

Page 23: ......