52

53

104 72 57-26

104 72 57-26

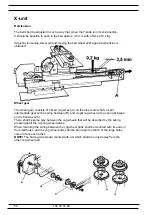

X-unit

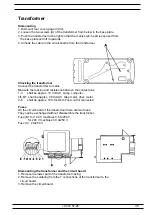

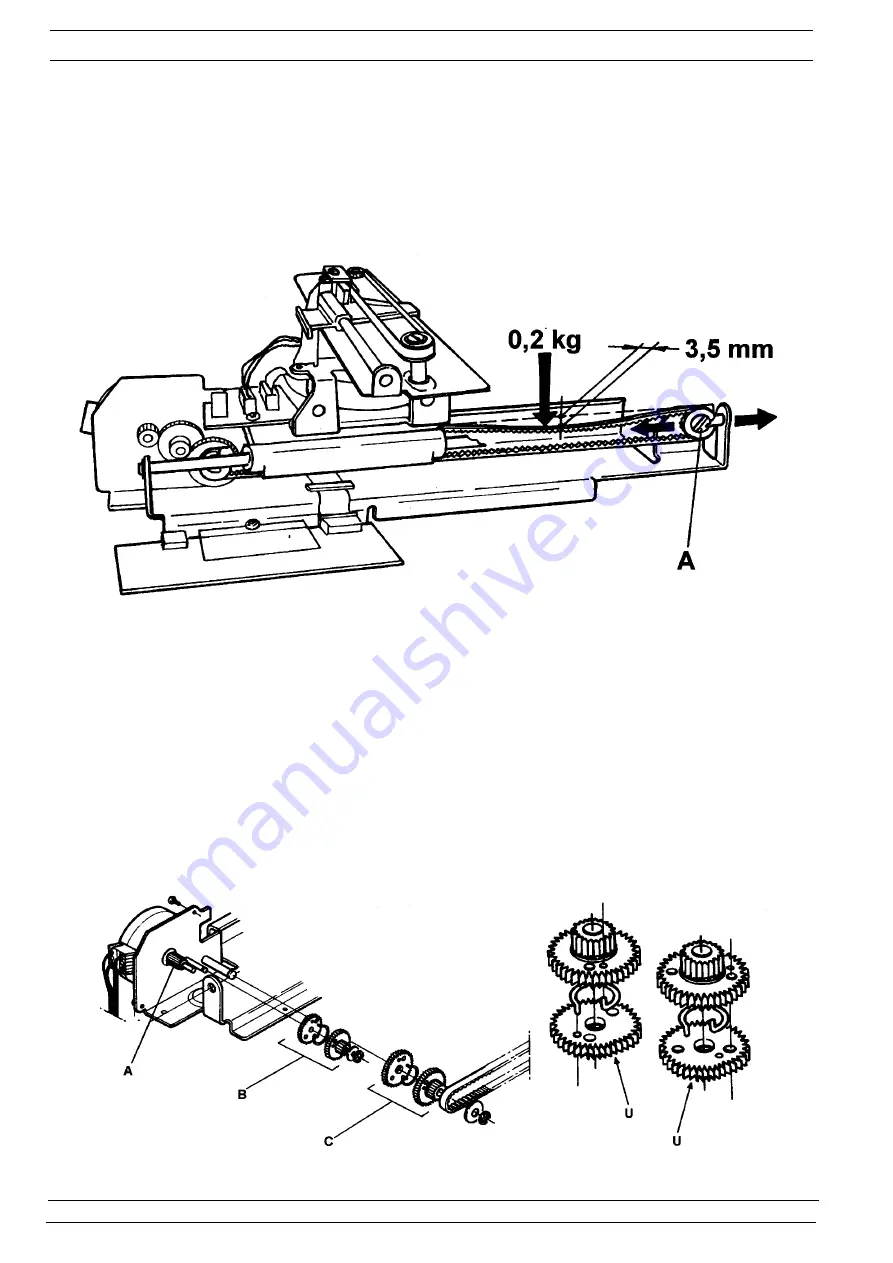

Belt tension

The belt shall be adjusted in such a way that, when the Y-slide is in its end position,

it should be possible to push in the belt

approx. 3,5 mm with a force of 0,2 kg.

Adjust by loosening screw (A) and moving the belt wheel until a good belt tension is

obtained.

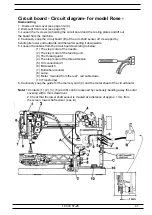

Wheel gear

The wheel gear consists of a fixed cog wheel (A) on the step motor shaft, a split

intermediate gear with a spring between (B), and a split cog wheel with a spring between

on the belt wheel (C).

There shall be some play

between the cog wheels that will be absorbed by the spring

pressing apart the two cog wheel halves.

When mounting the spring between the cog wheel parts shall be mounted with its ends in

the small holes

,

and the cog wheel parts shall be bent apart so that 2 of the large holes

come to face each other.

NOTE!

The flat cog wheels are marked with a U which shall be turned away from the

other cog wheel part.