replaced. If brushes wear rapidly, check for

excessive brush tension and roughness or high

mica on the commutator. Brush spring tension

should be from 24 to 28 ounces.

Starting Motor Disassembl

y

At regular intervals, (the actual time

depending on the type of operation) the

starting motor should be disassembled for a

thorough cleaning and inspection of all

parts. The Bendix drive should be cleaned and

oiled with a penetrating oil as any accumu-

lation of dirt on the drive might restrict

the free movement of the pinion. Never clean

the armature or fields in any degreasing

tank, or grease dissolving materials, since

these may damage the insulation. The commu-

tator should be trued in a lathe if neces-

sary. Replace all parts showing excessive

wear. All wiring connections should be

checked. Rosin flux should be used in making

soldered connections. Acid flux must never

be used on electrical connections. Submit

reassembled unit to NO-LOAD and LOCK tests.

Checking of Improperly Operating

Starting Motor

If the starting motor does not develop rated

torque and cranks the engine slowly or not

at all, check the battery, battery terminals

and connections, and battery cables.

Corroded, frayed, ,or broken cables should

be replaced and loose or dirty connections

corrected. The starting motor switch should

be checked for burned contacts and the switch

replaced if necessary.

If all these are in order, remove the cover

band of the starting motor and inspect the

brushes and commutator. The brushes should

form good contact with the correct brush

spring tension. A dirty commutator can be

cleaned with a strip of No. 00 sandpaper held

against the commutator with a stick while the

starting motor operates. NEVER USE EMERY

CLOTH TO CLEAN COMMUTATOR. If the commutator

is very dirty, or burned, or has high mica,

remove the armature from the cranking motor

and take a cut off the commutator in a lathe.

The mica should be undercut to a depth of

1/32".

If there are burned bars on the commutator,

it may indicate open circuited armature coils

which will prevent proper cranking. Inspect

the soldered connections at the commutator

riser bars. An open armature will show

excessive arcing at the commutator bar which

is open on the no-load test.

Tight or dirty bearings will reduce

armature speed or prevent the armature from

turning. A worn bearing, bent shaft, or loose

field pole screws will allow the armature to

drag on the pole shoes causing slow speed or

failure of the armature to revolve. Check for

these conditions.

If the brushes, brush spring tension, and

commutator appear in good condition, the

battery and external circuit found satisfac-

tory, and the starting motor still does not

operate correctly, it will be necessary to

remove the starting motor for no-load and

torque checks.

NO-LOAD TEST: Connect the starting motor

in series with a battery of the specified

voltage and an ammeter capable of reading

several hundreds amperes. If an R.P.M.

indicator is available, read the armature

24

T E C H N I C A L S E R V I C E M A N U A L

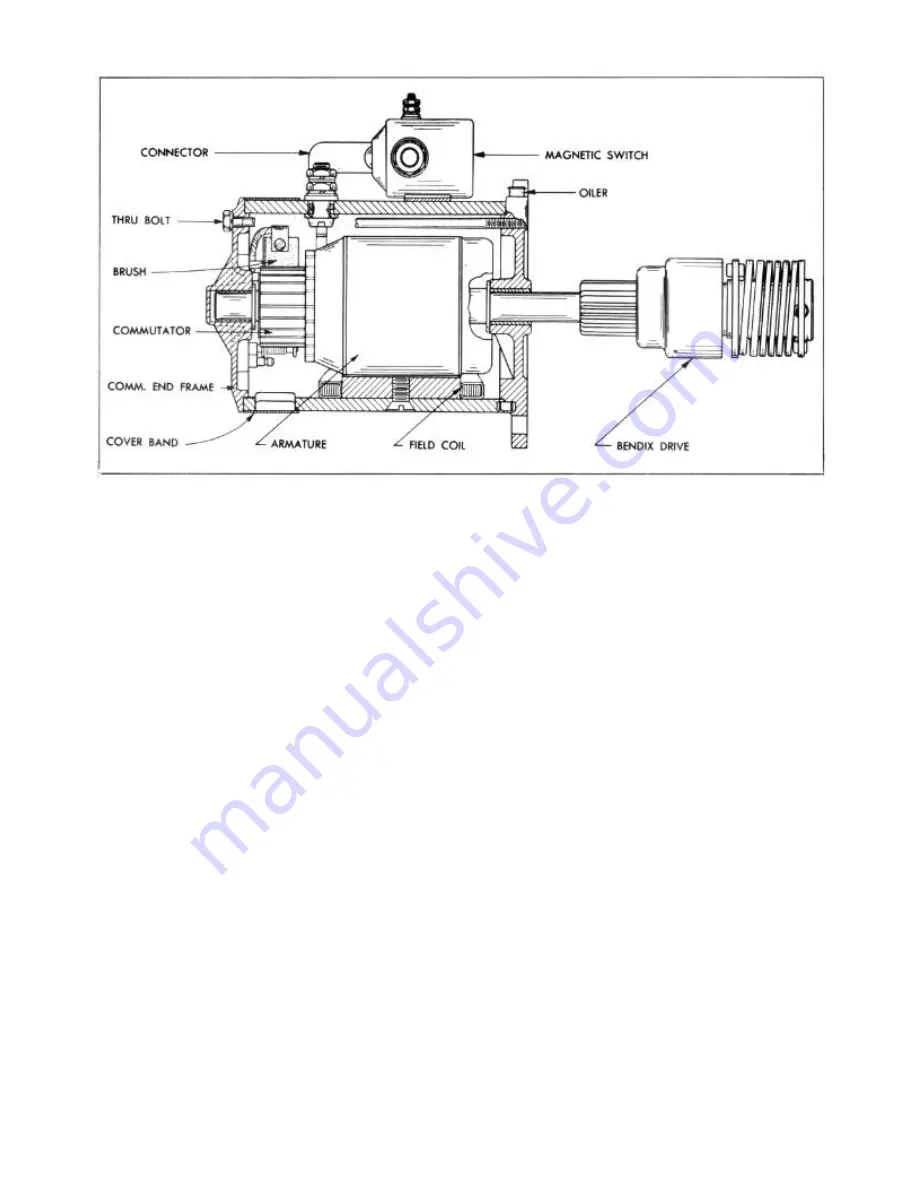

FIGURE 24—

"Rambler" Series Starting Motor (Regular or Overdrive Transmission)

Summary of Contents for 1955 Rambler

Page 1: ......

Page 2: ......

Page 3: ......

Page 4: ......

Page 28: ......

Page 38: ......

Page 42: ......

Page 87: ...46 T E C H N I C A L S E R V I C E M A N U A L...

Page 88: ...ELECTRICAL WIRING DIAGRAMS...

Page 89: ......

Page 90: ......

Page 91: ...ELECTRICAL WIRING DIAGRAMS...

Page 92: ......

Page 93: ......

Page 94: ......

Page 95: ......

Page 96: ......

Page 97: ......

Page 98: ......

Page 99: ......

Page 100: ......

Page 101: ......

Page 102: ......

Page 103: ......

Page 119: ......

Page 127: ......

Page 151: ...OVERDRIVE 5...

Page 165: ......

Page 179: ......

Page 199: ......

Page 200: ...2 TECHNICAL SERVICE MANUAL...

Page 223: ......

Page 243: ......

Page 251: ......

Page 255: ...ALL SEASON AIR CONDITIONING SYSTEM 5 Figure 2 Freon 12 Temperature Pressure Relation Curve...

Page 287: ......

Page 288: ......

Page 289: ......

Page 291: ......

Page 292: ......