9

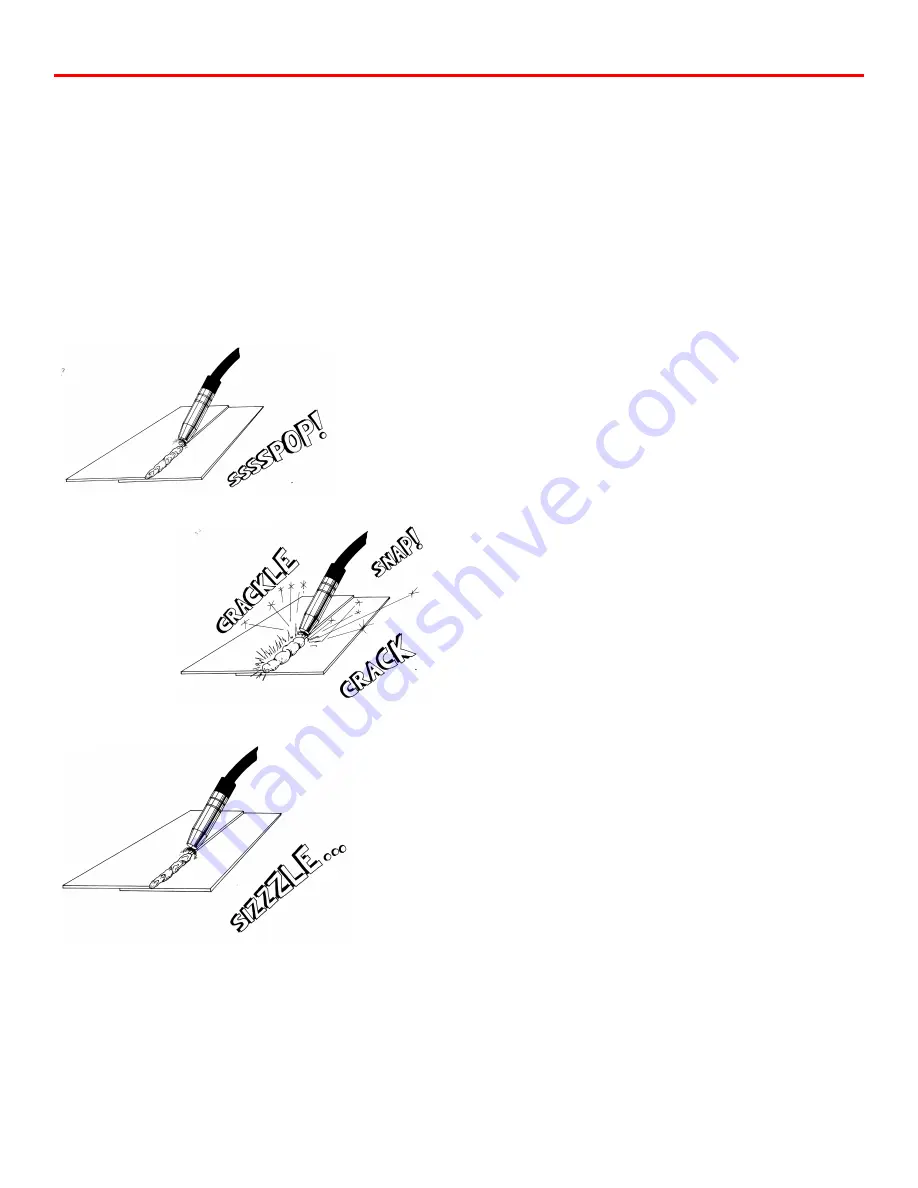

A hissing, blowing sound with a ball of molten wire forming at

the end of the wire and then dropping off indicates the wire feed

rate is too slow (See Fig. X). This means that the wire is

melting before it reaches the metal. A loud, cracking noise with

red hot wire coming out of the gun and the wire pushing the

gun away from the work indicates the wire feed rate is too fast

(See Fig. Y). This means that the wire is melting beyond the

weld and is not melting properly. When “tuned in” properly, a

steady frying noise can be heard (See Fig. Z). This means that

the wire is melting properly, and is melting right at the surface

of the weld.

When tuning in your welding machine, it is best to start with the

wire feed rate too high. On the highest power setting, you may

actually want to start with the wire feed rate set at maximum.

Gradually decrease the wire feed rate until the steady frying

noise is heard. A common problem many people have when

trying to tune the wire feed rate is that they turn the knob too

rapidly. Many people never turn the wire feed rate down low

enough, and then start to increase it again. If the wire feed rate

is slowly decreased, then eventually you will cross the point

where the machine will be tuned in. It is a good idea to practice

tuning in the welding machine. Start with the Voltage setting at

#4, as it has a nice, crisp sizzle. Once you have mastered tuning

in the machine on Voltage Setting #4, practice tuning in the

machine on different Voltage Settings.

It is highly recommended that you practice with your welder at

different Voltage Settings so that you will become familiar with

your welder. This is important to do prior to welding on your

project so you will know which voltage setting to select for an

application.

SEAM WELDING

Install the conical nozzle (Part #15105) on the welding gun.

The conical nozzle is used because it is much easier to see the

welding process due to the taper in the nozzle. Have 1/4" to

1/2" of welding wire protruding from the end of the gas nozzle.

Prior to running a seam weld, it is recommended that tack welds

be placed every 2 to 3 inches along the seam, even closer for

extremely thin panels. Tack welds will help to hold the panel in

place while welding, as well as to prevent panel separation

caused by warpage.

Hold the welding gun at a 45-degree angle and use the edge of

the gas nozzle to hold the two panels together, aim the welding

wire at the spot to be tacked. Momentarily press the trigger

(approximately 1 second) and tack the two panels together. Do

not lift up the welding gun until the weld has set. Tack welding

is done at the same power setting at which seam welding is

done. Select the correct voltage setting based on Chart 3 for the

material you are welding.

When you have the panel tacked into place, you are ready to

seam weld. Once again, have 1/4" to 1/2" of welding wire

protruding from the gas nozzle. The welding gun is generally

held at a 45-degree angle to the work piece. It may also be

tilted at a 45-degree angle to the side. Rest the gun nozzle on

the work piece and have the wire pointing at the spot where the

welding is to begin. Press the trigger and begin welding. It is

important that you can see the welding wire coming out of the

gas nozzle and the small halo formed at the end of the welding

wire where it is melting. This halo will provide the light

necessary to see through your helmet while welding.

Figure x

Figure y

Figure z

Summary of Contents for MTS 160

Page 21: ...21 Wiring Diagram MTS 160...

Page 22: ...Parts Breakdown MTS 160 22...