1) Power Indicator Lamp

This lamp is illuminated when the On-Off switch (#7) on the

front of your MTS 160 is turned to the on position and the

machine is connected properly to a 220-volt power supply.

2) Welding Current Indicator Lamp

When the trigger switch on either the TIG torch or the MIG gun

is depressed, welding current will be applied to the welding

torch and the Welding Current Indicator Lamp will be

illuminated.

If your MTS 160 is in the stick-welding mode, the welding

current indicator lamp will be illuminated all the time.

3) Thermoswitch Indicator Lamp

The thermoswitch indicator lamp will light up when the duty

cycle of your MTS 160 has been exceeded. When this lamp is

illuminated, the machine will no longer weld because the

machine has overheated. Leave the machine plugged in and

turned on so the cooling fans can cool the unit down. Allow the

machine to cool for 15 to 30 minutes, the thermoswitch should

reset automatically and your MTS 160 will be ready to weld.

4) Wire Feed Incher

The wire feed incher allows you to feed welding wire into the

welding gun with out wasting shield gas. Depressing the wire

feed incher will start the drive motor, feeding the welding wire.

Note the welding wire will only feed with the side panel closed.

5) Post Gas Flow

The post gas flow is adjustable from 1 sec to 4 sec. Post gas

flow is necessary during TIG welding, because after the arc is

extinguished if the gas stopped flowing immediately, there is

a possibility the molten weld puddle would come in contact

with the atmosphere, causing weld defects. Additionally it

prevents the tungsten from becoming contaminated by the

atmosphere. The gas flow should run long enough to allow

the orange color of the tungsten to disappear. It is important

to remember not to remove the TIG torch from the weld until

the post gas cycle has been completed. If you are welding at

higher amperages or on more critical alloys it may be

necessary to increase the post gas flow to a higher value.

6) Burn Back Time

When MIG welding, as soon as you release the trigger on the

welding gun, the wire feed motor stops turning immediately.

The Burnback Time is the amount of time your welder is still

applying welding current to the welding wire after the wire

feed motor has stopped feeding the welding wire. If the

current stopped at the same time the motor stopped turning,

there is a chance the welding wire would “freeze” in the

molten welding puddle as it solidified. If there is too much

Burnback Time, the wire will melt to the contact tip.

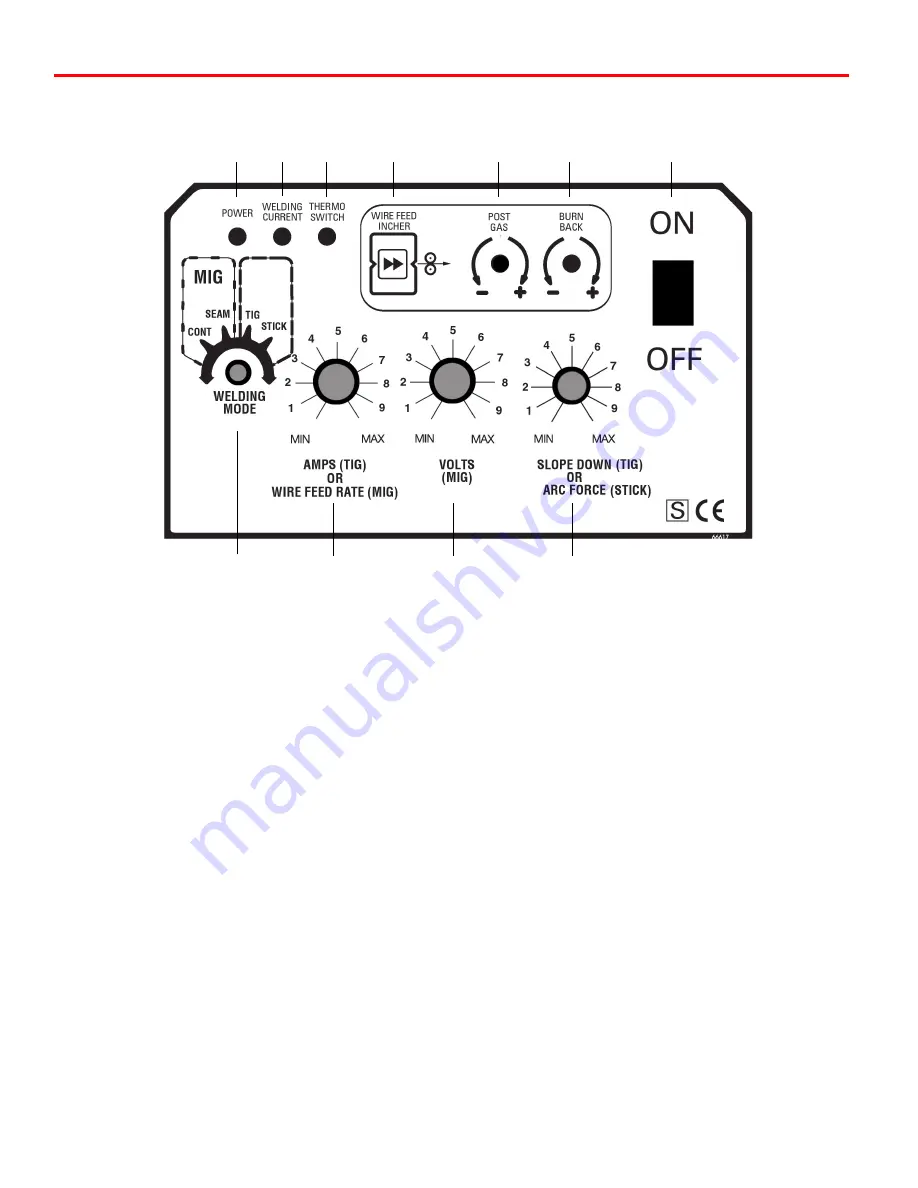

4

Front Panel Controls

1

2

3

4

5

6

7

8

9

10

11

Figure 1

Summary of Contents for MTS 160

Page 21: ...21 Wiring Diagram MTS 160...

Page 22: ...Parts Breakdown MTS 160 22...