10

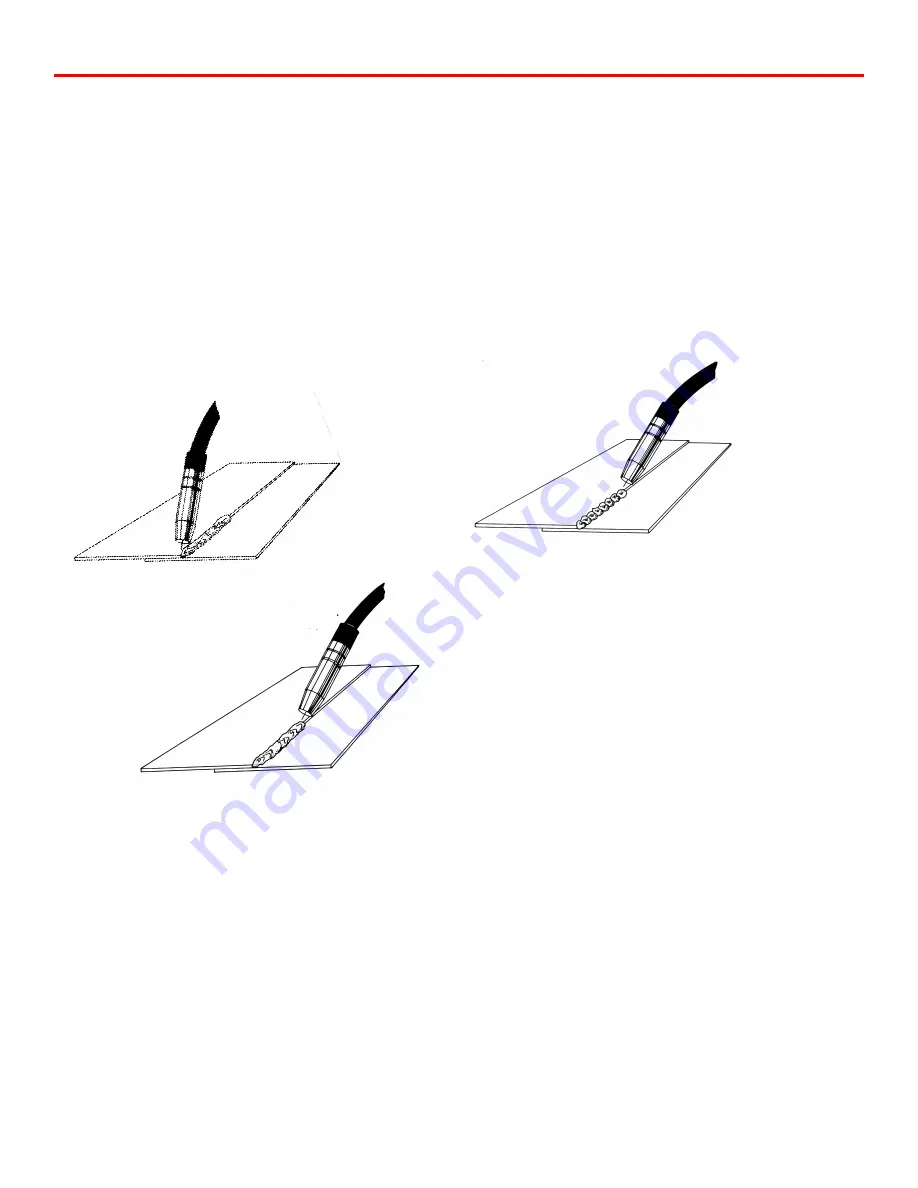

The direction in which the welder travels will affect the

characteristics of the weld. When “pushing the weld” the

welding gun is tilted away from the direction of travel

(See Fig. 4). When “pulling the weld” the welding gun is tilted

toward the direction of travel (See Fig. 5).

As you gain expertise with your welder, you will find that is

possible to reduce warpage when welding sheet metal by

welding at a higher power setting and moving faster along the

seam. In this way, you are reducing the amount of time

welding, therefore reducing the amount of heat which is put into

the panel.

STITCH WELDING

Your HTP MTS 160 can perform a manual stitch weld. Stitch

welding refers to a method of welding where you will weld,

pause, weld, pause and continue in this cycle. This method

produces a welded seam which is actually a series of

overlapping spot welds that give the appearance of “Fish

Scales”. Stitch Welding is recommended for use on very thin

materials, such as thin body panels or rusty exhaust pipe and in

areas where it is desired to keep warpage to a minimum. Stitch

welding is also good for welders who have a problem keeping a

steady hand, or maintaining a constant travel rate.

Stitch welding is performed with the conical nozzle (15105),

small conical nozzle (15108), or the cylindrical nozzle (15104)

and the decision is up to the operator. For manual stitch

welding, the trigger on the welding gun is depressed until 3/16"

diameter puddle of metal is deposited on the workpiece.

Release the trigger and move the welding gun so that the center

of the next puddle will lie on the edge of the first puddle. Wait

for the orange glow from the first puddle to disappear and

deposit the second puddle of metal. Continue this process until

the seam is completed.

For a given thickness of metal, stitch welding is performed at

the same or one power setting lower than seam welding. Stitch

welding can be done on both steel and aluminum, and is

recommended under 120 amps. Stitch welding at higher power

settings can result in serious burnback problems.

SPOT WELDING

Install the spot weld nozzle (Part #15106) on the welding gun.

Using the Punch & Flange Tool (Part #12005 {5/16"} or

#12003 {3/16"}) or the Heavy Duty Hole Punch (#12009)

punch holes in the upper panel to be spotted on. Feed some

welding wire out past the end of the spot weld nozzle. Using

sidecutters, clip the welding wire off flush with the end of the

spot weld prongs. This will aid you in centering the gas nozzle

over the punched hole.

Select the correct voltage setting from the chart 3 (page 8) and

increase by approximately 2 numbers. Tune in the wire feed rate

until the proper frying noise is heard. Reduce the wire feed rate

just until the machine begins to sound out of tune. A slightly

slower wire feed rate will produce flatter spot welds for spot

welds which are vertical down, however, do not reduce the wire

feed rate when performing overhead spot welds. Place the

welding gun over the punched hole so that the welding wire is

centered over the punched hole (See Fig. 7). Depress the

trigger on the welding gun. Release the trigger as soon as the

hole is filled. Examine the spot weld. If the hole is not

completely full, either the welding wire was not centered over

the hole or the trigger was released too soon. If the spot weld is

Figure 5 “Pulling the Weld”

Figure 4 “Pushing the Weld”

Figure 6

“Stitch Welding”

Summary of Contents for MTS 160

Page 21: ...21 Wiring Diagram MTS 160...

Page 22: ...Parts Breakdown MTS 160 22...