15

LP-171 Rev. 3.3.15

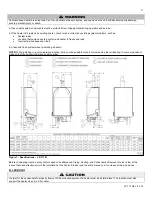

C. WALL MOUNTING INSTRUCTIONS

This heater is heavy and awkward to lift. It is recommended and safer to install the heater with two people. Use caution as to not drop

the heater, which could damage the heater and cause property damage and/or personal injury. Verify that the heater is securely

mounted before leaving unsupervised. Failure to comply with the above and properly mount the heater could result in substantial

property damage, severe personal injury, or death.

The wall must be vertically plumb and capable of carrying the weight of the heater and its related components.

The building frame (studs) must be 16" on center. If not, you must use 1/2" minimum plywood 24" x 48", fastened with at least (14) #12

x 3" (3/16" x 3") round head tapping screws to the frame of the building to provide proper support for the heater. Alternate methods of

mounting must not be used. (ex. toggle bolts, hollow wall anchors) or any other fastener other than #12 x 3" (3/16" x 3") round head

tapping screws.

If the heater is not vertically plumb, improper and unsatisfactory operation may occur, causing excessive condensation build-up,

nuisance fault codes, and unnecessary maintenance.

D. INSTALLATION STEPS

1. Prior to lifting the heater onto the wall, use the enclosed template to level and locate the 2 primary (#12 x 3" [3/16" x 3"]) round head

tapping screws, leaving about 1/4" between the screw head and the wall surface to allow for access to the keyway slot located in the

back of the heater panel. It is extremely important that the line on the template is level when locating the first 2 screws. Failure to do so

will result in an uneven or out of level installation.

2. Remove the heater cover. Locate the 2 keyway slots over the screws. Then lower the heater onto the smallest part of the keyway

slot.

3. Once the heater is mounted on the first 2 screws, finish tightening the screws to the back panel. Then install the 6 additional screws

of the same size to the back panel holes. This will provide additional strength and support to the heater.

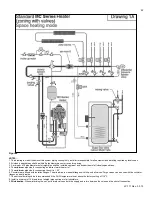

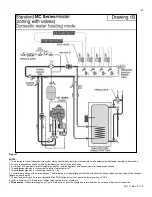

PART 5 – HEATER PIPING

Failure to follow the instructions in this section WILL VOID the warranty and may result in property damage, serious injury, or death.

Plumbing of this product should only be done by a qualified, licensed plumber in accordance with all local plumbing codes. The heater

may be connected to a storage tank to supply domestic hot water. HTP offers 60/80/119/175 gallon size storage tanks in either

stainless steel or glass-lined construction. These storage tanks can be directly connected to the heater supply and return connection.

A. GENERAL PIPING INFORMATION

The building piping system must meet or exceed the piping requirements in this manual.

Use two wrenches when tightening water piping at heater. Use one wrench to prevent the heater return or supply line from turning.

Failure to prevent piping connections from turning could cause damage to heater components.

Never use dielectric unions or galvanized steel fittings when connecting to a stainless steel storage tank or heater. Use only copper or

brass fittings. Teflon thread sealant must be used on all connections. All piping and components connected to the heater must be

approved for potable water systems.

The National Standard Plumbing Code, the National Plumbing Code of Canada, and the Uniform Plumbing Code limit the pressure of

the heat transfer fluid to less than the minimum working pressure of the potable water system up to 30 psi maximum. The heat transfer

fluid must be water or other non-toxic fluid having a toxicity of Class 1, as listed in Clinical Toxicology of Commercial Products, 5

th

Edition.

Summary of Contents for MC120

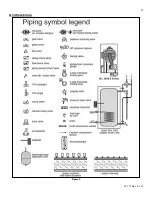

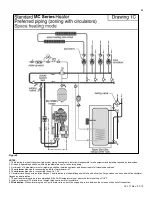

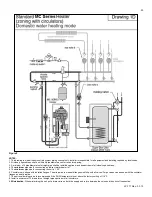

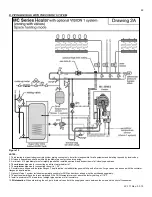

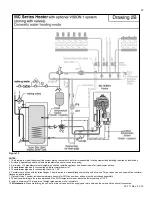

Page 21: ...21 LP 171 Rev 3 3 15 M PIPING DETAILS Figure 5 ...

Page 53: ...53 LP 171 Rev 3 3 15 Figure 30 ...

Page 71: ...71 LP 171 Rev 3 3 15 Figure 34 ...

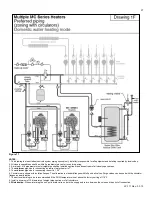

Page 72: ...72 LP 171 Rev 3 3 15 Figure 35 ...

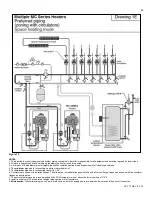

Page 73: ...73 LP 171 Rev 3 3 15 Figure 36 ...

Page 76: ...76 LP 171 Rev 3 3 15 ...

Page 77: ...77 LP 171 Rev 3 3 15 ...