10

LP-171 Rev. 3.3.15

C. OPTIONAL EQUIPMENT

Below is a list of optional equipment available from HTP. These additional options may be purchased through your HTP distributor:

Indirect Tank Sensor (Part # 7250P-325)

Outdoor sensor (Part # 7250P-319)

2” Stainless Steel Outside Termination Vent Kit (V500)

3” Stainless Steel Outside Termination Vent Kit (V1000)

2” PVC Concentric Vent Kit (Part # KGAVT0501CVT)

3" PVC Concentric Vent Kit (Part # KGAVT0601CVT)

3” Polypro Vent Kit (Part # 8400P-001)

3” Polypro Pipe (33’ length Part # 8400P-002, 49.5’ length Part # 8400P-003)

Alarm System (Part # 7350P-602) (to monitor any failure)

Condensate Pump (Part # 7250P-320)

Condensate Neutralizer (Part # 554200)

Vision 1 Outdoor Sensing System (Part # 7250P-622)

PART 3 – PREPARE HEATER LOCATION

Carefully consider installation when determining heater location. Please read the entire manual before attempting installation. Failure to

properly take factors such as heater venting, piping, condensate removal, and wiring into account before installation could result in

wasted time, money, and possible property damage and personal injury.

A. BEFORE LOCATING THE HEATER

Incorrect ambient conditions can lead to damage to the heating system and put safe operation at risk. Ensure that the heater installation

location adheres to the information included in this manual. Failure to do so could result in property damage, serious personal injury, or

death.

Failure of heater or components due to incorrect operating conditions IS NOT covered by product warranty.

1. Installation Area (Mechanical Room) Operating Conditions

Ensure ambient temperatures are higher than 32

o

F/0

o

C and lower than 104

o

F/40

o

C.

Prevent the air from becoming contaminated by the products, places, and conditions listed in this manual, Part 3, Section F.

Avoid continuously high levels of humidity

Never close existing ventilation openings

The service life of the heater

’s exposed metallic surfaces, such as the casing, as well as internal surfaces, such as the heat exchanger,

are directly influenced by proximity to damp and salty marine environments. In such areas, higher concentration levels of chlorides from

sea spray coupled with relative humidity can lead to degradation of the heat exchanger and other heater components. In these

environments, heaters must not be installed using direct vent systems which draw outdoor air for combustion. Such heaters must be

installed using room air for combustion. Indoor air will have a much lower relative humidity and, hence, potential corrosion will be

minimized.

This heater is certified for indoor installations only. Do not install the heater outdoors. Failure to install this heater indoors could result in

substantial property damage, severe personal injury, or death.

2. Check for nearby connections to:

System water piping

Venting connections

Gas supply piping

Electrical power

Condensate drain

3. Check area around heater. Remove any combustible materials, gasoline, and other flammable liquids.

Summary of Contents for MC120

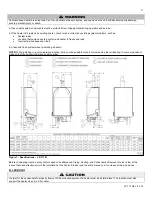

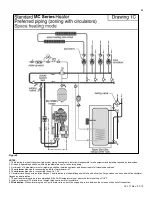

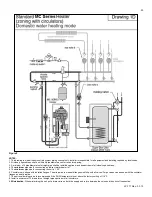

Page 21: ...21 LP 171 Rev 3 3 15 M PIPING DETAILS Figure 5 ...

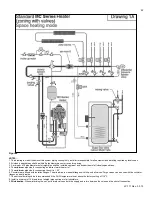

Page 53: ...53 LP 171 Rev 3 3 15 Figure 30 ...

Page 71: ...71 LP 171 Rev 3 3 15 Figure 34 ...

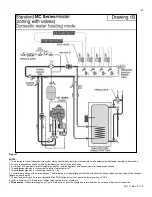

Page 72: ...72 LP 171 Rev 3 3 15 Figure 35 ...

Page 73: ...73 LP 171 Rev 3 3 15 Figure 36 ...

Page 76: ...76 LP 171 Rev 3 3 15 ...

Page 77: ...77 LP 171 Rev 3 3 15 ...