66

LP-171 Rev. 3.3.15

Table 14

926 Control Board FAULT

Code

Description

Remedy

F00

High temperature switch

limit exceeded 194

o

F.

1. Check circulation pump operation.

2. Assure that there is adequate flow through the heater by accessing the status menu and assuring that there

is less than a 50

o

F rise from the return thermister to the supply thermister.

3. Check thermister reading on supply thermister. Replace switch if faulty.

F01

Vent temperature limit

exceeded.

1. Push the red reset button on the vent temperature limit switch.

2. Check module overheat switch. Disconnect the wires plugged into the switch and measure continuity across

the switch.

3. Check the flue temperature during operation using a combustion analyzer.

4. Replace the vent limit switch if faulty. Replace module overheat switch if open.

F02

Interrupted or shorted

supply (outlet) thermister.

1. Check the electrical connection to the thermister on the outlet manifold.

2. If connection is okay, replace thermister.

F03

Interrupted or shorted

return (inlet) thermister.

1. Check the electrical connection to the thermister on the outlet manifold.

2. If connection is okay, replace thermister.

F05

Supply (outlet) temperature

exceeds 230

o

F.

1. Check circulation pump operation.

2. Assure that there is adequate flow through the heater by accessing the status menu and assuring that there

is less than a 50

o

F rise from the return thermister to the supply thermister.

F06

Return (inlet) temperature

exceeds 230

o

F.

1. Check circulation pump operation.

2. Assure that there is adequate flow through the heater by accessing the status menu and assuring that there

is less than a 50

o

F rise from the return thermister to the supply thermister.

926 CONTROL BOARD ERROR CODES

CODE

DESCRIPTION

DURATION

CORRECTIVE ACTION

FOU

Outdoor sensor is open,

shorted, or outdoor

temperature is below -40

o

F

Until Corrected

1. Disconnect the outdoor sensor from the wiring and measure its resistance.

Compare the measured resistance to the table in this manual to see if it

corresponds to the temperature of the sensor. If the resistance does not

agree with the sensor, replace the sensor.

2. If the resistance is OK, disconnect the sensor wiring from both the boiler

and the sensor and check continuity using an ohmmeter. Repair or replace as

necessary.

E03

The system sensor is open or

shorted

Until Corrected

1. Disconnect the system sensor from the wiring and measure its resistance.

Compare the measured resistance to the table in this manual to see if it

corresponds to the temperature of the sensor. If the resistance does not

agree with the sensor, replace the sensor.

2. If the resistance is OK, disconnect the sensor wiring from both the boiler

and the sensor and check continuity using an ohmmeter. Repair or replace as

necessary.

E19

The line voltage frequency is

out of range

Until Corrected

Inspect power wiring to boiler and repair as necessary. If connected to line

voltage, notify the power company. If connected to an alternate power source

such as generator or inverter, make sure the line voltage frequency supplied

by the device is 60 Hz.

PRO

Water Pressure Switch is

Open

Until Corrected

1. Assure that the system pressure is above 10 psig.

2. Check for leaks in the system piping.

FLU

Blocked Vent Pressure

Switch open, Condensate

Cup Full, Condensate Cup

not present

Until Corrected

1. Check the flue vent to be sure it is not blocked or damaged.

2. Check the blocked vent pressure switch operation by applying a jumper.

(If the switch is not functioning properly, replace it.

3. If the condensate cup is excessively full, check the condensate piping

system for piping and proper drainage. Repair as necessary. If the

condensate cup is not excessively full and is in place, remove the cup and

check the operation of the float switch in the cup. The float should pivot

freely in the cup and the back of the float should contact the stem of the

switch when in the down position.

4. Reinstall the condensate cup. While doing so, check the operation of the

cup-in-place switch. The switch should contact the protrusion on the plastic

socket that the cup is secured into and trip when the cup is snapped into

place.

5. Check to be sure that the 2 pin condensate cup connector is securely

plugged into the socket on the bottom of the heater.

6. If FLU code is still present and the cause not found, check continuity of

wiring from the flue switch to the condensate cup connector (pink wires) and

from the condensate cup connector through the condensate float switch and

condensate cup-in-place switch. These three devices are all wired in series

with each other. Repair any wiring or replace defective components if

necessary.

Do not “Jump Out” any of the devices in this circuit. These

devices ensure product safety and must be in place and

connected at all times of normal operation.

Summary of Contents for MC120

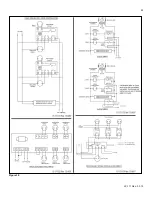

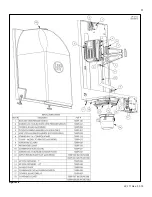

Page 21: ...21 LP 171 Rev 3 3 15 M PIPING DETAILS Figure 5 ...

Page 53: ...53 LP 171 Rev 3 3 15 Figure 30 ...

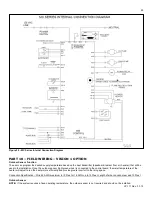

Page 71: ...71 LP 171 Rev 3 3 15 Figure 34 ...

Page 72: ...72 LP 171 Rev 3 3 15 Figure 35 ...

Page 73: ...73 LP 171 Rev 3 3 15 Figure 36 ...

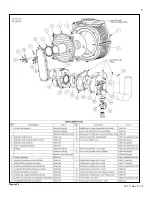

Page 76: ...76 LP 171 Rev 3 3 15 ...

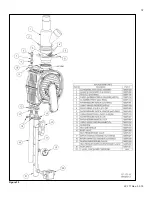

Page 77: ...77 LP 171 Rev 3 3 15 ...