HP D300 Digital Dispenser

26

4.

Click

OK

. All dispensing for the current fluid will occur. In the main operating window, only the

wells for the current fluid are shown, and each well is covered with an X while it is being

dispensed and then turns black when the dispensing for that well is complete.

5.

Repeat steps 1 through 4 to load and dispense each fluid in the plate configuration. Fluid

loading can occur during the dispense operation; you do not have to wait until the current

Dispensehead has finished. Just remember to click on

OK

as each fluid is loaded in its

Dispensehead, or to click on

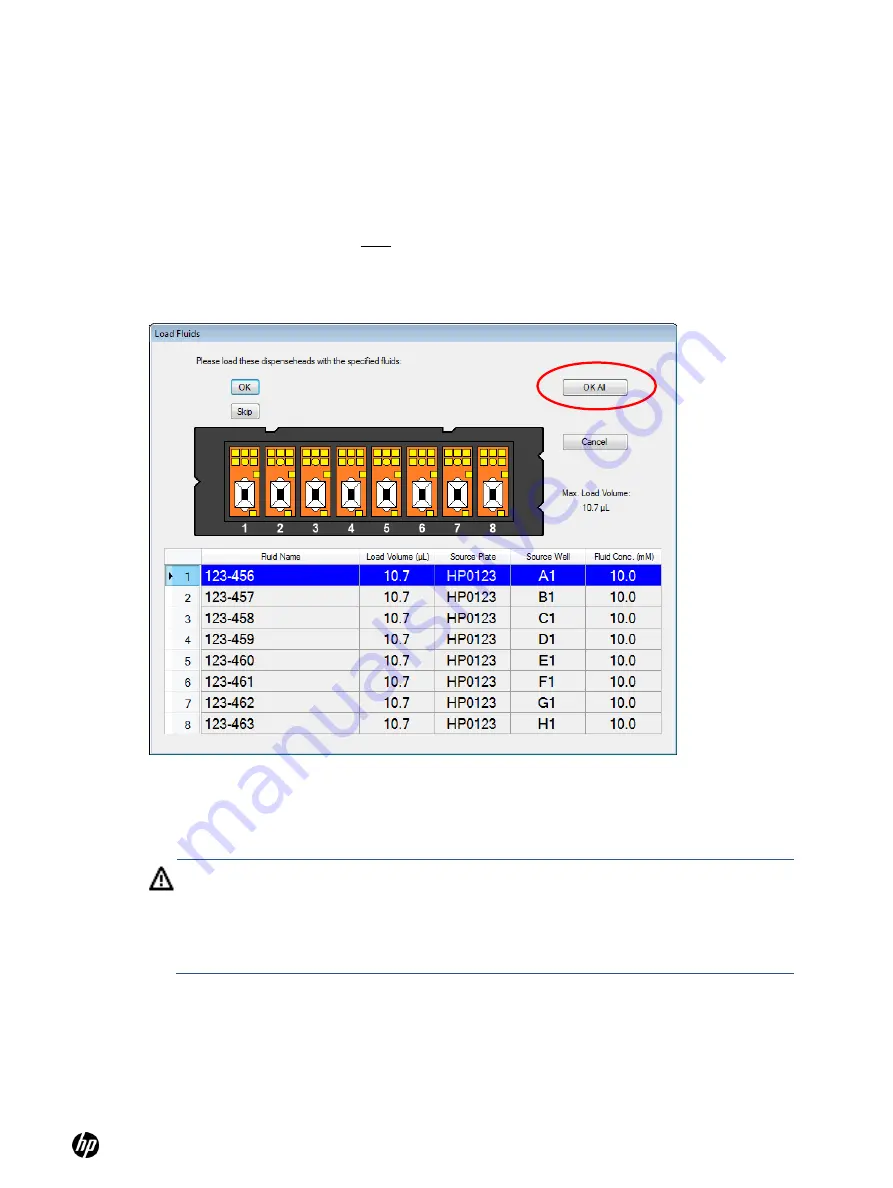

OK All

when all Dispenseheads of the current Cassette are

loaded, as shown in

6.

If loading all Dispenseheads simultaneously with a multichannel pipette or individually prior to

starting the dispense, then after all Dispenseheads of the current Cassette are loaded, click on

OK All

Figure 4-26

Load fluid dialog box showing OK All button

7.

After the fluids in the currently loaded cassette are dispensed into plate 1, then depending

upon the configuration, you will be asked to either load a new cassette or a new plate. Read

the prompt dialog box carefully to determine the next step.

WARNING:

For multiplate configurations, the D300 software first minimizes the use of

dispenseheads, so that fluids which are used on multiple plates are dispensed into all of

those plates as long as the total dispense volume for that fluid does not exceed 10uL. This

dispensehead conservation can result in a non-intuitive plate loading order. Be careful to

load the correct well plate as prompted by the software! Minimizing the number of

dispenseheads used may sometimes result in more plate swaps than expected.

8.

If you are prompted to load the next plate in the configuration, you will see a prompt similar to

, where you can enter or scan a name for the plate. If the plate has been loaded

previously, you will be prompted with the plate name you previously entered or scanned in for

the plate, along with the plate number.