Honeywell

Parameter Descriptions

71

10

9.5

U

NDERLOAD

PROTECTION

0

= No response

1

= Alarm

2

= Fault, stop according to P2.3

The purpose of the motor underload protection is to ensure that there is load

on the motor when the drive is running. If the motor loses its load there might

be a problem in the process, e.g. a broken belt or a dry pump.

The underload protection time limit is 20 seconds, which is the maximum time

allowed for an underload state to exist before causing a trip according to this

parameter.

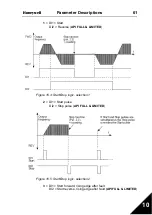

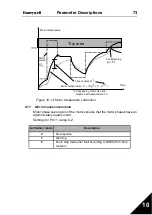

Figure 10.12: Underload protection

9.7

T

HERMAL

PROTECTION

OF

THE

MOTOR

0

= No response

1

= Warning

2 =

Fault, stop mode after fault according to parameter 2.3

If tripping is selected the drive will stop and activate the fault stage. Deactivat-

ing the protection, i.e. setting parameter to 0, will reset the thermal model of

the motor to 0%.

9.8

M

OTOR

AMBIENT

TEMPERATURE

When the motor ambient temperature must be taken into consideration, it is

recommended to set a value for this parameter. The value can be set between

-20 and 100 degrees Celsius.

Underload curve at

zero freq. = 10%

f

5 Hz

Underload curve at

nominal freq. = 50%

Field weakening

point, P1.11

Underload area

Torque