14

Installation

Honeywell

4

4. INSTALLATION

4.1 MECHANICAL INSTALLATION

There are two possible ways to mount the SmartVFD COMPACT to the wall; either

screw or DIN-rail mounting. The mounting dimensions are given on the back of the

drive and on the following page.

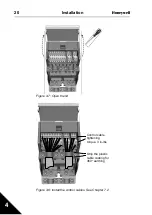

Figure 4.1: Screw mounting

Figure 4.2: DIN-rail mounting

MI2-3

MI1

=M 4

=M 5

1

2