63-4309—2

32

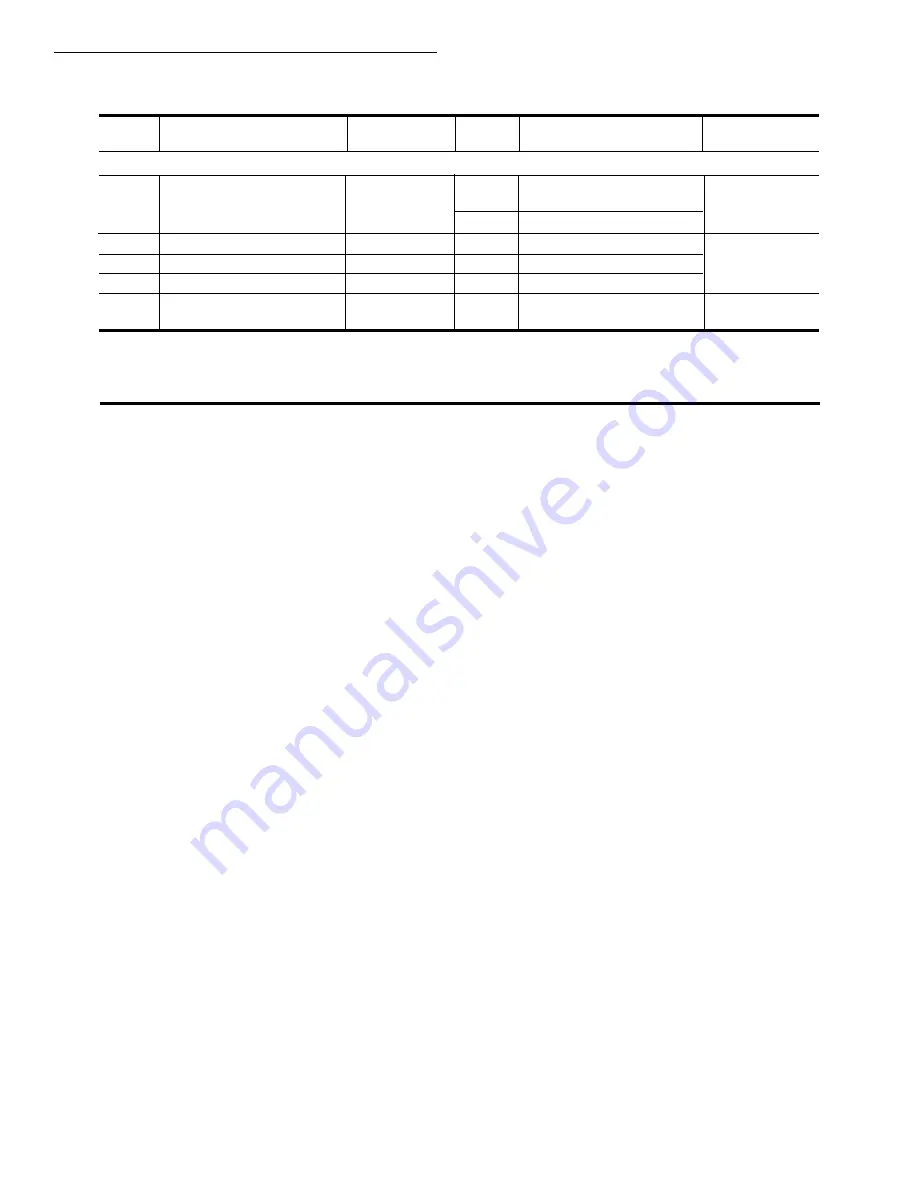

OPTIONAL (continued)

205

[DO] AIR_OK

N/A

157

[DI] AIR_FL or

Must be

configured.

6

[AI] V_PRES

206

[DO] OD_DMP

N/A

None

N/A

209

[DO] VBOX+

N/A

None

215

[DO] OCCUP

N/A

None

216

[DO] DP_VLV

N/A

[DI] FRE_CL

Must be

configured.

VAV CONFIGURATION REQUIREMENTS (continued)

Control

Value

Control

Dependent

Dependent

Number

Variable Required

Required

Number

Variable Required

Value Required

PM7600B

PM7600B INPUT AND OUTPUT OPTIONS • OPERATION

Operation

The W7600 Control Module provides customized soft-

ware to maintain consistent discharge air temperature and

duct static pressure in Variable Air Volume (VAV) sys-

tems. Efficient control of supply fan, economizer, heating

and cooling equipment is essential to the W7600 system.

The system also provides monitoring and alarm for safety

inputs to protect VAV equipment. Control responds to a

Proportional plus Integral plus Derivative (P+I+D) algo-

rithm with specific strategies for heating, cooling and static

pressure. The P+I+D control algorithm eliminates offset

between the setpoint and the sensed temperature for precise

discharge air temperature and static pressure control. The

algorithm allows setpoint control within a specified sensi-

tivity range throughout all load conditions.

The system offers numerous input and output options

including analog outputs for modulating control, and digi-

tal outputs for energizing and de-energizing stages of heat-

ing and cooling. Inputs and outputs are user programmable,

as are control parameters such as number of stages, mini-

mum on/off times, reset type, motor speed, etc. Discharge

air temperature and static pressure setpoints are individu-

ally user programmable. Space or return air temperature is

monitored and heating may be energized when the tem-

perature drops below a programmable setpoint. The system

provides a programmable morning warm-up setpoint that is

monitored for transition from night mode to occupied tem-

perature. This setpoint also enables a changeover to heat

mode during the occupied mode if the temperature drops

below setpoint. The system also provides night setback and

morning warm-up in the heat mode. In cool mode, the

system allows shut-down for the unoccupied period. Out-

door air temperature may be monitored. The W7600 sys-

tem maintains discharge air temperature and duct static

pressure based on user programmable setpoint and control

band parameters. Setpoint is defined as the desired tem-

perature and pressure conditions. Control band is a devia-

tion band around the setpoint that is acceptable in the duct.

Discharge air or duct static conditions that are above the

cooling setpoint or below the heating setpoint generate a

demand signal to control the system as outlined in this

specification.

NOTE: THE W7600 VAV control algorithm reads the

analog inputs every fifteen seconds, with the exception of

analog input 1, which is read every five seconds. The

controlled outputs are updated every fifteen seconds,

with the exception of the pressure output, which is up-

dated every five seconds. Analog outputs (modulating)

change the controlled device at the rate of one percent per

second; i.e., 0 percent requires 100 seconds. The control-

ler determines whether it should change from cooling to

heating or from heating to cooling mode once per minute.

Minimum on and off times for heating and cooling must

be satisfied before the changeover can occur.

CHARACTERISTICS OF PROPORTIONAL,

PROPORTIONAL PLUG INTEGRAL (P+I) AND

PROPORTIONAL PLUS INTEGRAL PLUS DE-

RIVATIVE CONTROL (P+I+D)

The user can configure the proportional, integral and

derivative gains in the control algorithm to adjust the

control to the user’s needs. However,

it is recommended

that the default settings be used whenever possible to

avoid erratic control of temperature and static pres-

sure

. The characteristics of the control options are dis-

cussed below.

PROPORTIONAL CONTROL

In proportional control, the final control element moves

to a position proportional to the deviation of the value of the

controlled variable from the setpoint. The position of the

final control element is a linear function of the value of the

controlled variable.

PROPORTIONAL-INTEGRAL (PI) CONTROL

Proportional-integral (PI) control, also called

propor-

tional-plus-reset

control, virtually eliminates offset and

makes the proportional band nearly invisible. The major