❏

7. Tightly tape the wing halves together with several strips

of masking tape on the top and bottom. Continue to wipe away

excess epoxy as it comes out. Be certain the front and back of

both wings accurately align. Do not disturb the wing until the

epoxy has hardened.

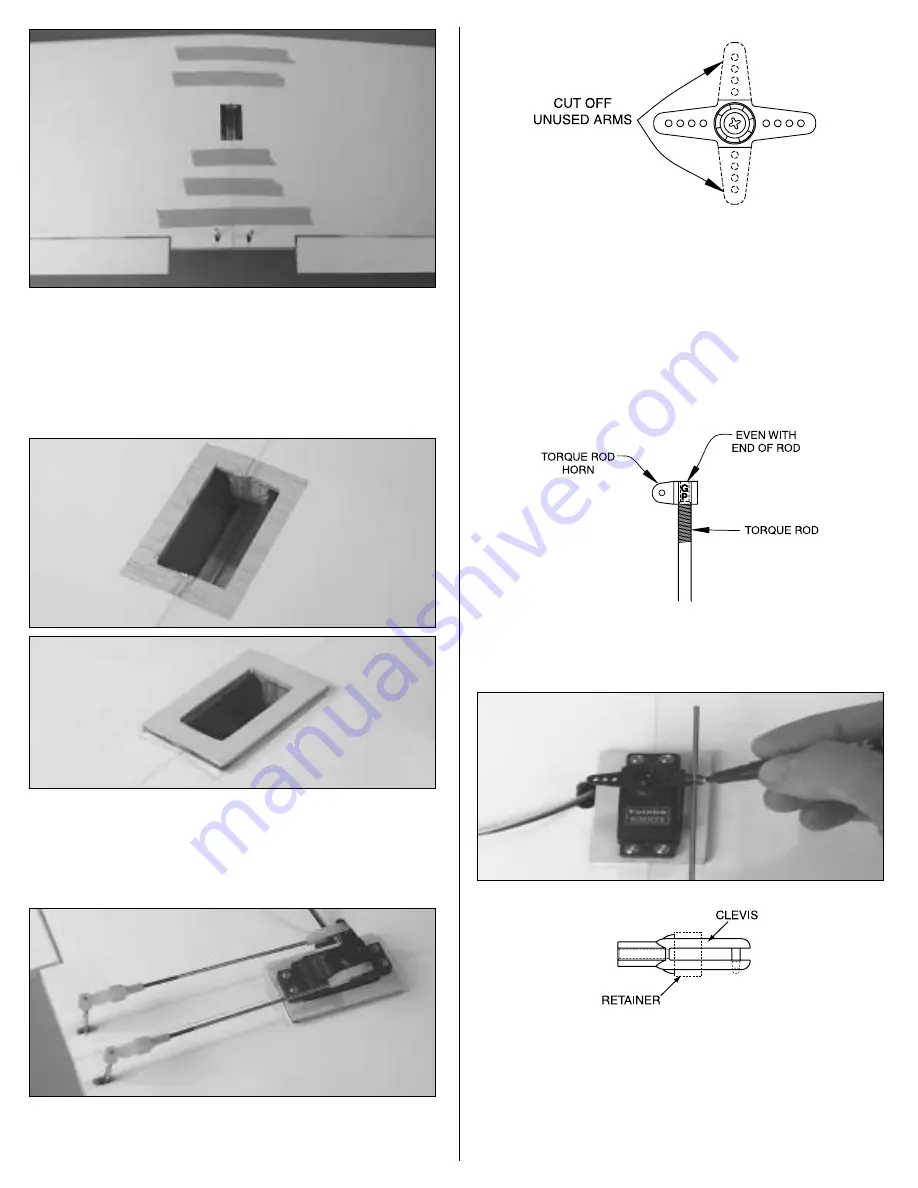

Hook Up the Ailerons

❏

1. Cut the covering from the bottom of the wing for the 1/8"

[3mm] plywood aileron servo mount. Glue the servo mount to

the wing with epoxy. Make sure the mount is level and fill the

gap on both sides with epoxy.

Refer to this photo for the following seven steps.

❏

2. Cut a hole in the sheeting so the servo wire can come

through (the hole can be seen in the photo at step 6). Guide the

servo wire out the hole and install the servo.

❏

3. Use wire cutters to cut two of the arms off a four-arm

servo arm. Install the arm on the aileron servo.

❏

4. Drill 1/16" [1.6mm] holes through the servo mount for the

servo mounting screws, then temporarily mount the servo using

the eyelets, rubber grommets and screws that came with it.

Remove the screws, add a few drops of thin CA to the holes,

allow to fully harden, then remount the servo. This process is

important to harden the “threads” in the wood so the screws

remain tight.

❏

5. Thread the nylon torque rod horns onto the aileron torque

rods until the horns are even with the ends of the torque rods.

❏

6. Thread a nylon clevis twenty full turns onto a 6" [150mm]

wire pushrod that is threaded on one end. Connect the clevis

to the torque rod horn. Align the pushrod with the servo arm,

then use a fine-point felt-tip pen to mark the pushrod where it

crosses the servo holes. Note: The aileron must be centered

during this procedure (the bottom of the aileron should be even

with the bottom of the wing).

8