❏

4. If you are not able to achieve these settings, more or less

movement may be required from the throttle pushrod. The

same as the control surface throws, this is done by relocating

the screw-lock pushrod connector on the servo arm to another

hole, or by relocating the clevis on the carburetor arm to the

other hole.

❏

5. Install the muffler if you have not yet done so.

❏

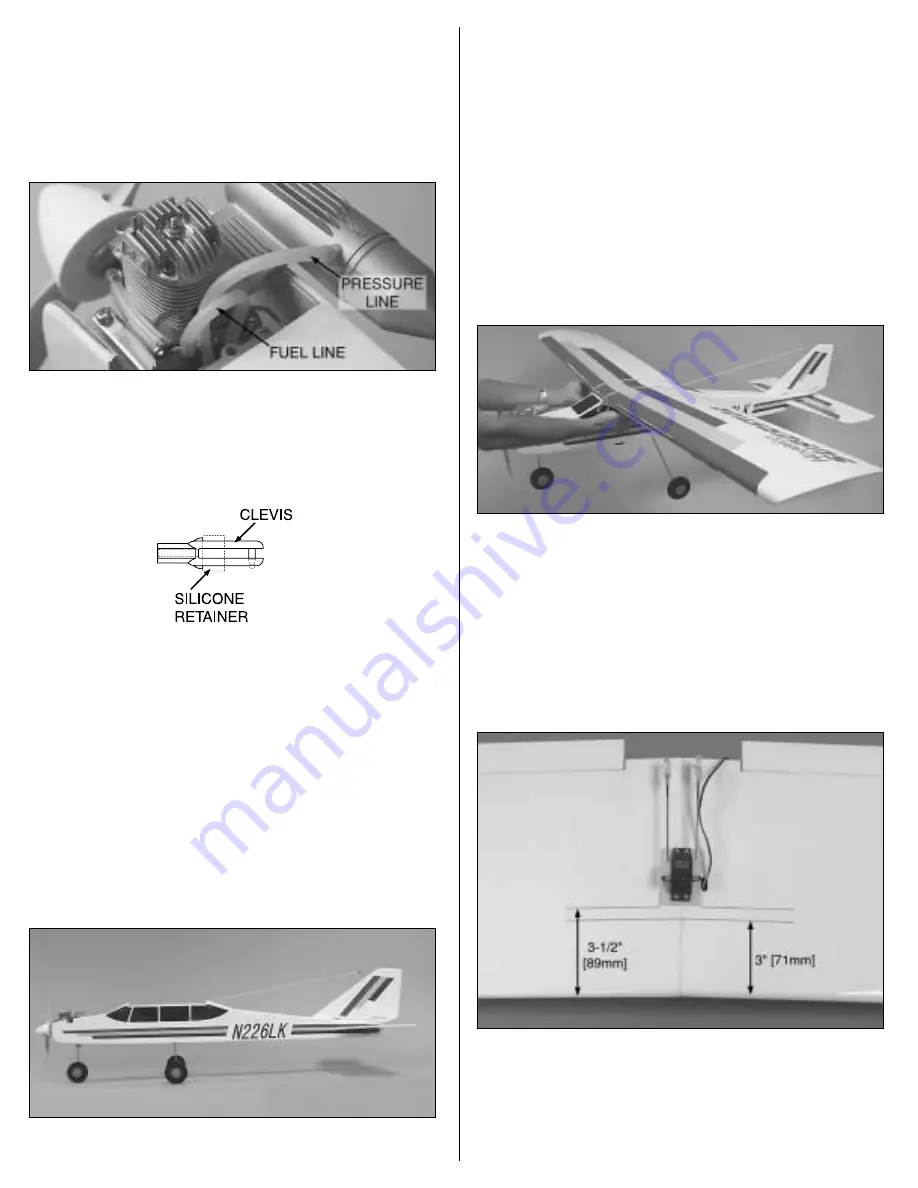

6. Connect the fuel lines. If your tank was assembled as

shown in the photo on page 12, the fitting coming from the left

side of the fuel tank goes to the muffler (pressure line) and the

other fitting goes to the carburetor (fuel line) or to the needle

valve if you have a remote needle such as on the O.S.

®

MAX

LA .40 shown.

❏

7. Insert and tighten the screws that hold the servo

arms on all four servos. Install a silicone retainer on the

clevises on the elevator and rudder servo arms and on the aileron

torque rod horns.

Identify Your Model

Whether you fly at an R/C club site or somewhere on your own,

you should have your name, telephone number, address and

AMA number on or in your model so it can be identified and

returned in case it lands somewhere away from the flying site.

Fill out the I.D. tag on page 23 and use spray adhesive or tape

to attach it inside the fuselage.

Check the Ground Stance

Place the model on your workbench and view it from the side.

In order to taxi, takeoff and land well, the model must sit level

on the landing gear as shown. If the model does not sit level,

or, if after a hard landing the main landing gear has bent

upward, remove the main landing gear and use a bench vise

or pliers to bend it back down to achieve the correct ground

stance. If

(when) you bend the nose gear, it should be bent

back to its original position as well.

Balance the Model

This important step is also referred to as “checking the C.G.”

(center of gravity). Simply stated, the

center of gravity is the

point at which the model balances when lifted under the wing.

If the C.G. is too far forward, the model will be “nose-heavy”

and could be difficult to takeoff and land and lose some of its

self-correcting tendencies. If the C.G. is too far aft, the model

will be “tail-heavy” and the controls may be too sensitive,

making the model too difficult to control–especially for an

inexperienced pilot! DO NOT DISREGARD THIS STEP! Follow

the instructions to balance the model correctly, thus giving you

the greatest chances for success!

❏

1. Use narrow tape or a felt-tip pen to mark two lines on the

bottom of the wing 3" [71mm] and 3-1/2" [89mm] from the

leading edge.

❏

2. Make certain the model is in “ready-to-fly” condition with

all components mounted and installed (propeller, spinner,

landing gear, etc.). The fuel tank must be empty.

19