17

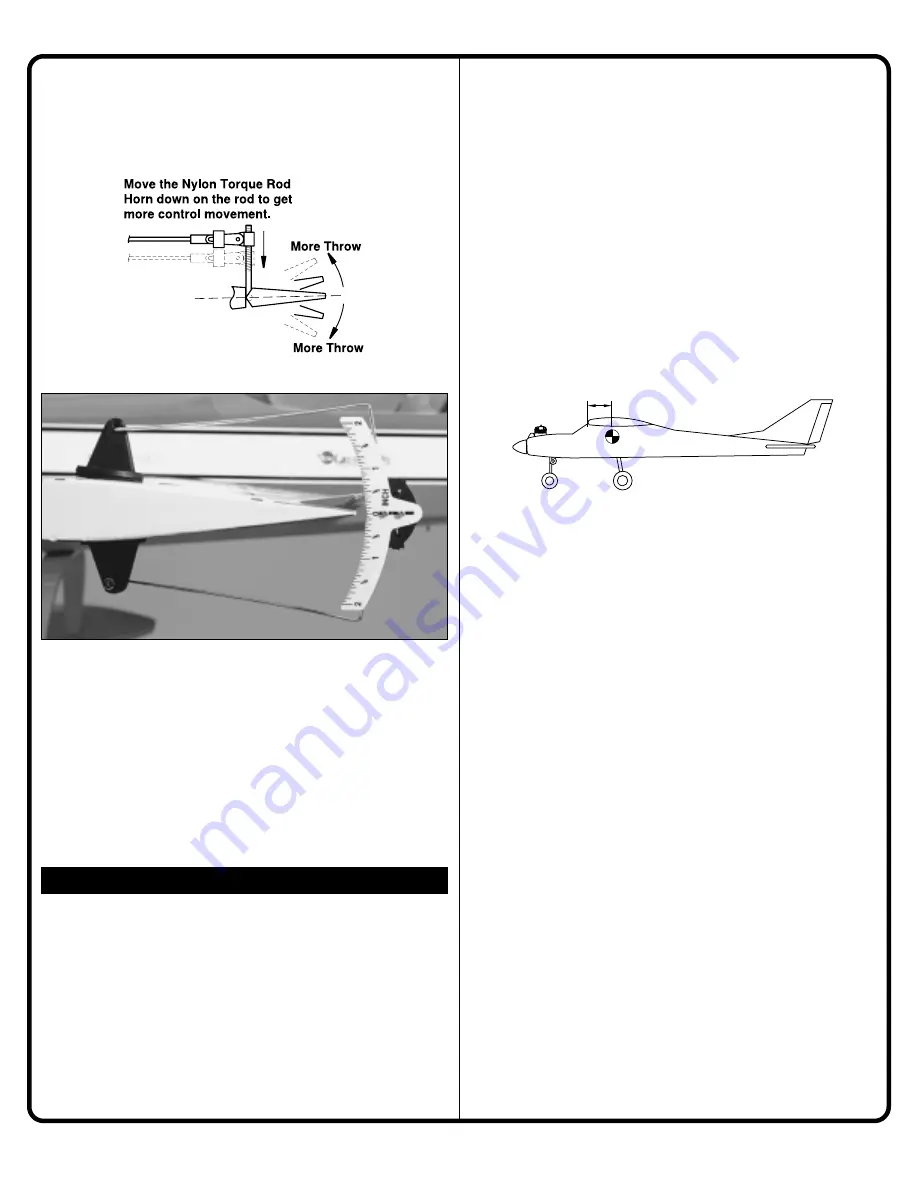

If you need more control movement, you can move the nylon

horn closer to the control surface or you can move the rod at

the servo away from the center of the servo horn. If you have

too much movement, reverse the process.

One leading cause of crashes is flying an airplane with its

control throws set differently from those recommended in the

instructions. The Great Planes AccuThrow

™

lets you quickly

and easily measure actual throws first, so you can make

necessary corrections before you fly. Large, no-slip rubber feet

provide a firm grip on covered surfaces without denting or

marring the finish. Spring tension holds AccuThrow’s plastic

ruler steady by each control surface. Curved to match control

motions, the ruler provides exact readings in both standard or

metric measurements.

GPMR2405.

CHECK THE LATERAL BALANCE

Now that you have the model completed, this is a good time to

balance the airplane laterally (side-to-side). Here is how to

do it:

❏

1. Attach the wing to the fuselage.

❏

2. With the airplane sitting level, lift the model by the engine

propeller shaft and the bottom of the fuselage at the tail (this

may require two people). Do this several times.

❏

3. If one wing always drops when you lift the model, it

means that side is heavy. Balance the airplane by attaching

weight to the lighter wing tip.

Note:

An airplane that has been

laterally balanced will track better in loops and other

maneuvers. Balancing weight is available from your local

hobby dealer.

CHECK THE FORE-AFT BALANCE (CENTER OF GRAVITY)

Note:

This section is

VERY

important and must

NOT

be

omitted! A model that is not properly balanced will be unstable

and possibly unflyable.

❏

1. Accurately mark the balance point on the bottom of the

wing on both sides of the fuselage. The balance point is

located 3-3/8” (85mm) back from the leading edge. This is the

balance point at which your model should balance for your first

flights. Later, you may wish to experiment by shifting the

balance up to 1/4" (6mm) forward or back to change the flying

characteristics. Moving the balance forward may improve the

smoothness and arrow-like tracking, but it may then require

more speed for takeoff and make it more difficult to slow down

for landing. Moving the balance aft makes the model more

agile with a lighter and snappier “feel”. In any case, please

start at the location we recommend and do not at any time

balance your model outside the recommended range.

❏

2. With the wing attached to the fuselage, all parts of the

model installed (ready to fly), and an

empty

fuel tank, position

your fingertips at the marked balance point.

❏

3. Lift the model. If the tail drops when you lift, the model is

“tail heavy” and you must add weight* to the nose. If the nose

drops, it is “nose heavy” and you must add weight* to the tail

to balance.

Note:

Nose weight may be easily installed by using a Heavy

Spinner Hub or gluing lead weights to the firewall. Tail weight

may be added by using Great Planes (GPMQ4485) “stick-on”

lead weights.

*If possible, first attempt to balance the model by changing the

position of the receiver battery and receiver. If you are unable

to obtain good balance by doing so, then it will be necessary

to add lead weights to the nose or tail to achieve the proper

balance point.

CG

3-3/8"

(85mm)

BALANCE YOUR MODEL

IMPORTANT!