17

GB

Cutting Technique

The main objectives are to avoid overheating the

wheel, and to prevent it from being pinched or

trapped or stressed in any way.

z

Adjust position of wheel guard to direct the

discharge away from you.

z

Prepare to make straight cuts only. Use a snap-

line to mark long cuts, and follow the marked

line carefully.

z

Take a balanced, comfortable stance on the left

side of the cutter. Hold cutter fi rmly with both

hands.

z

Always throttle up to cutting speed before letting

the wheel make contact. The cutter may be

jerked forward, causing loss of control, if wheel

is in contact during throttling up. Carefully let

cutting edge of wheel make light contact with

the work. Do not push or bounce the wheel onto

the work. Hold cutter steady. Do not let it tilt or

wobble.

z

Do not let the wheel stop in one place, but keep

it moving - in one direction, or back and forth,

along the line of cut. Cutting in one spot causes

heat build-up which can damage or glaze the

wheel. Too much cutting pressure also causes

overheating.

z

Cut as shallow and straight a groove as you can.

If you cut a curve, the wheel will start to bind as

the cut deepens.

z

Go over and over the groove you have started

until the cut is completed.

z

On cuts of long duration, remove cutter from cut

often to let the wheel cool.

z

Never put any side pressure on a cutter wheel,

grind on the side of it or use it to fl ick away

debris.

z

When cutting large diameter pipe, cut 360

degrees around and try not to cut through. If a

large segment of the wheel breaks through, the

wheel may catch and kick out at lightning-fast

speed.

z

Before cutting materials which are not supported

along their entire length, provide support to

prevent binding. Also be aware that the top

section will settle on the wheel if a column is cut

in two.

NOTE

Always cut at full throttle. Cutting at less than full

throttle may harm the clutch as it will overheat

during slippage.

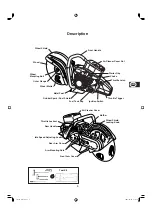

DANGER

Do not cut with the portion of the wheel

running from just below horizontal to just

past top dead center. This is the zone of

contact where the cutter is likely to be kicked

upward and backward towards you.

Kickback

Danger Zone

Follow Snap Line

Keep Wheel

Moving

Cut in a

Straight Line

Cutter will Bind

in Crocked Cut

Roll Pipe to Cut 360° Around

Try not to Let Wheel Break

Through in One Place

CM14E̲WE̲all.indb 17

CM14E̲WE̲all.indb 17

2008/02/05 21:09:32

2008/02/05 21:09:32