10

Fault reports and their corrections

70

No. Fault report

Cause of fault

Fault correction

073

LAMBDA CALIBRATION

Lambda probe calibration outside

the limit range or error during

lambda calibration

clean lambda probe

✆

- contracting party

074

AIR FLOW SENSOR

Cable break; Air flow sensor does

not provide a signal

check sensor

075

air flow

The set air flow setpoint value could

not be reached

Check or clean the heat exchanger /

flue gas pipe

Check lifting unit

✆

- contracting party

076

Fuel

*Pre-filling / Ignition insert can not

be performed because no fuel

Notification FIRE OUT occurs for

the second time within 2 hours

*during operation intermediate

hopper is not full despite power

reduction

Check fuel level

Check burning parameters, adjust

as adapt

Clean intermediate hopper level

sensor

077

Additional input

Digital input responds to additional

input

check the unit connected to the

input

078

NIVEAU LEVEL

Active intermediate hopper level

sensor; low fuel level at

intermediate hopper

Check fuel level

Check discharge system (motor,

screw, springs)

080

MP ROOM DISCHARGE

Digital input motor protection room

discharge has responded

motor protection acknowledge

Check discharge system (motor,

screw, springs)

Remove debris

081

SPEED ID-FAN

Speed outside the limits for more

than 10 seconds

Check connection rotation speed

sensor

Check ID-fan

✆

✆

- contracting party

082

GRATE CLEANING 1

Grate cleaning failure; motor

damaged; grate linkage damaged or

loosened; misaligned grate sensor

Check grate cleaning motor

Check grate linkage

Check grate cleaning end switch

✆

- contracting party

083

GRATE CLEANING 2

Failure grate cleaning; impossible to

close grate; grate got stuck; grate

linkage damaged or loosened

Remove debris

Check grate cleaning motor

Check grate linkage

Check grate cleaning end switch

✆

- contracting party

084

GRATE CLEANING 3

Grate was opened during the

combustion

Check grate cleaning motor

Check grate linkage

Check grate cleaning end switch

085

SUCTION MODE

maximum suction cycles exceeded

(with suction discharge)

maximum suction time exceeded

(with internal suction hopper)

Adjust suction cycles

Check discharge system (motor,

screw)

Check fuel quality

086

SUCTION VALVE

Vacuum flap could not be opened

Check vacutrans damper

Check end switch vacutrans damper

087

ASH CONTAINER

Ash container door is opened

Connect ash container

Close ash container door

Summary of Contents for firematic CONDENSATION 30

Page 1: ...OPERATING INSTRUCTIONS Wood chips pellets heating system firematic CONDENSATION 30 40 ...

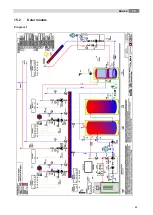

Page 83: ...Annex 15 83 15 ANNEX 15 1 Additional boiler module Hydraulic recommendation 1 ...

Page 84: ...15 Annex 84 Hydraulic recommendation 2 ...

Page 85: ...Annex 15 85 15 2 Solar module Program 1 ...

Page 86: ...15 Annex 86 Program 2 ...

Page 87: ...Annex 15 87 Program 3 ...

Page 88: ...15 Annex 88 Program 4 ...

Page 89: ...Annex 15 89 Program 5 ...

Page 90: ...15 Annex 90 Program 6 ...

Page 91: ...Notes 16 91 16 NOTES ...