11

Maintenance schedule

76

Item

Procedure

Check fault recognition and fault report

Check

if

fault

report

e.g.:

ASH

CONTAINER FAULT is shown

Safety valve

Check safety valve tightness

System pressure

Check system pressure

Minimum pressure: 1,5 bar (cold)

Maximum pressure: see boiler plate

Fire extinguisher

Check fire extinguisher securing and seal

as well as hose and nozzle (according to

national standard)

Ash storage

Ash has to be stored in a non flammable,

air tight container till disposal.

Boiler room

Remove flammable materials, except

wood chips or pellets stored in a

appropriate container, from the operating

room

Fire protection

Check structural fire protection and fire

doors (e.g.: self-locking fire door)

Condensate and

flushing water

drainage or lifting

station (if

available).

drain line

Inspection and function control of the

lifting unit and the pump or the

condensate / flushing water drain.

For longer drain lines, these must be

checked at regular intervals and, if

necessary cleaned by the customer.

Otherwise, there may be blockages in the

drainage area as deposits may not be

completely flushed away

Summary of Contents for firematic CONDENSATION 30

Page 1: ...OPERATING INSTRUCTIONS Wood chips pellets heating system firematic CONDENSATION 30 40 ...

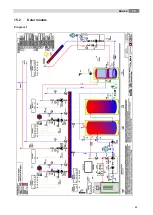

Page 83: ...Annex 15 83 15 ANNEX 15 1 Additional boiler module Hydraulic recommendation 1 ...

Page 84: ...15 Annex 84 Hydraulic recommendation 2 ...

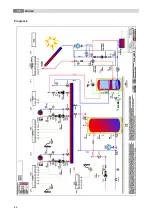

Page 85: ...Annex 15 85 15 2 Solar module Program 1 ...

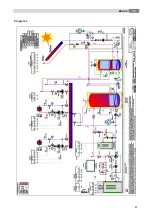

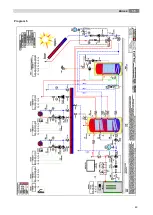

Page 86: ...15 Annex 86 Program 2 ...

Page 87: ...Annex 15 87 Program 3 ...

Page 88: ...15 Annex 88 Program 4 ...

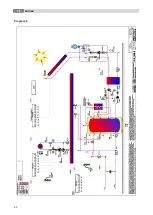

Page 89: ...Annex 15 89 Program 5 ...

Page 90: ...15 Annex 90 Program 6 ...

Page 91: ...Notes 16 91 16 NOTES ...