11

Maintenance schedule

80

11.4

Annually inspection

Annual inspection, at least every 3000 operating hours

Item

Procedure

Maintenance

Conduct system maintenance by authorised

personnel

Drives and

motors

Demount intermediate hopper covers

Check gear motor for abnormal or conspicuous

running noises by using the aggregate test

Check gear motor visually for damages and

wear (oil leakage, ..).

Flange bearing

Visually check of wear (see lubrication plan at

side 80)

Lubricate the chain and the bearing at the

outside

retighten worm screw

Burn back

protection device

Demount intermediate hopper cover

Unscrew revision cover

Check BFP flap visually for damages, wear

and tightness

Open BFP flap by using the aggregate test

Position paper strip between hopper flange

and BFP flap and close BFP flap afterwards.

Try to pull out paper strip. If possible, adjust

BFP flap.

Conduct paper strip test at different positions

Summary of Contents for BioFire 1000

Page 1: ...OPERATING INSTRUCTIONS Wood chips pellets heating system BioFire 500 600 800 1000 1250 1500 ...

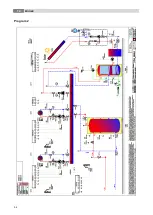

Page 89: ...Annex 14 89 14 ANNEX 14 1 Additional boiler module Hydraulic recommendation 1 ...

Page 90: ...14 Annex 90 Hydraulic recommendation 2 ...

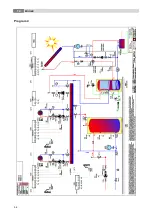

Page 91: ...Annex 14 91 14 2 Solar module Program 1 ...

Page 92: ...14 Annex 92 Program 2 ...

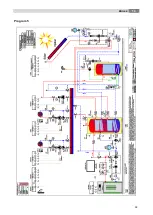

Page 93: ...Annex 14 93 Program 3 ...

Page 94: ...14 Annex 94 Program 4 ...

Page 95: ...Annex 14 95 Program 5 ...

Page 96: ...14 Annex 96 Program 6 ...

Page 97: ...Notes 15 97 15 NOTES ...