11

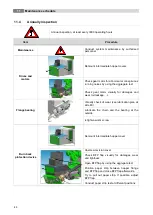

Maintenance schedule

78

ID-fan

cyclone

Function test of correct working of

the ID-fan by using the aggregate

test.

Check ID-Fan for abnormal or

conspicuous running noises.

At cyclone maintenance cover open

and if necessary ash remove in the

cone.

Thermal valve for

security heat

exchanger

Check

thermal

safety

valve

tightness/function.

Safety valve

Check safety valve tightness

System pressure

Check system pressure

Minimum pressure: 1,5 bar (cold)

Maximum pressure: see boiler plate

Fire extinguisher

Check fire extinguisher securing and

seal as well as hose and nozzle

(according to national standard)

Sensor barrier

screw off maintenance cap

Clean sensors on the inside of the

intermediate hopper with soft tissue

on the left and right (The cleaning

interval depends on the fuel and may

be necessary weekly if necessary).

Ash storage

Ash has to be stored in a non

flammable, air tight container till

disposal.

Boiler room

Remove flammable materials, except

wood chips or pellets stored in a

appropriate

container,

from

the

operating room

Fire protection

Check structural fire protection and

fire doors (e.g.: self-locking fire door)

Summary of Contents for BioFire 1000

Page 1: ...OPERATING INSTRUCTIONS Wood chips pellets heating system BioFire 500 600 800 1000 1250 1500 ...

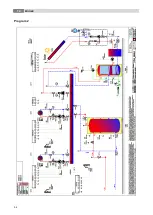

Page 89: ...Annex 14 89 14 ANNEX 14 1 Additional boiler module Hydraulic recommendation 1 ...

Page 90: ...14 Annex 90 Hydraulic recommendation 2 ...

Page 91: ...Annex 14 91 14 2 Solar module Program 1 ...

Page 92: ...14 Annex 92 Program 2 ...

Page 93: ...Annex 14 93 Program 3 ...

Page 94: ...14 Annex 94 Program 4 ...

Page 95: ...Annex 14 95 Program 5 ...

Page 96: ...14 Annex 96 Program 6 ...

Page 97: ...Notes 15 97 15 NOTES ...