53

Heat & Glo • MEZZO36-C/ST-C, MEZZO48-C/ST-C, MEZZO60-C/ST-C, MEZZO72-C/ST-C Installation Manual • 2600-980 Rev. D • 9/19

A. Fuel Conversion

• Make sure the appliance is compatible with available gas

types.

• Conversions must be made by a qualified service

technician using Hearth & Home Technologies specified

and approved parts.

B. Gas Pressure

• Verify inlet pressures. Verify minimum pressures when

other household gas appliances are operating.

• Install regulator upstream of valve if line pressure is

greater than 1/2 psig.

• Valve pressure taps are accessible by removing the

decorative barrier front and the bottom glass shield.

9

Gas Information

Gas Pressure

Natural Gas

Propane

Minimum inlet pressure

5.0 in. w.c.

11.0 in. w.c.

Maximum inlet pressure

10.0 in. w.c.

13.0 in. w.c.

Manifold pressure

3.5 in. w.c.

10.0 in. w.c.

Note:

Have the gas supply line installed in accordance with

local codes, if any. If not, follow ANSI Z223.1. Installation

should be done by a qualified installer approved and/or

licensed as required by the locality. (In the Commonwealth

of Massachusetts installation must be performed by a

licensed plumber or gas fitter).

Note:

A listed (and Commonwealth of Massachusetts ap

-

proved) 1/2 in. (13 mm) T-handle manual shut-off valve

and flexible gas connector are connected to the 1/2 in. (13

mm) control valve inlet.

• If substituting for these components, please consult

local codes for compliance.

Fire Risk.

Risk of Fire! Risk of Explosion!

Incorrect pressure will damage valve.

• Isolate

gas supply piping BEFORE pressure

testing gas line at test pressures above 1/2

psig.

• Close the manual shutoff valve BEFORE

pressure testing gas line at test pressures

equal to or less than 1/2 psig.

WARNING

• Optimum appliance performance requires proper input

pressures.

• Gas line sizing requirements will be determined in ANSI

Z223.1 National Fuel Gas Code in the USA and CAN/

CGA B149 in Canada.

• Pressure requirements when in operation are:

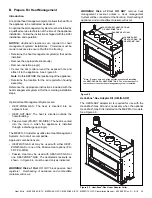

Figure 9.1 Valve Pressure Taps

VALVE PRESSURE TAPS

Note:

This appliance does include a manual gas shutoff

valve that is located in the valve compartment. This manual

gas shutoff valve is accessible for service by removing

the decorative barrier front and the bottom glass shield.

The valve is most accessible if it is located forward in the

control cavity of the appliance.

Depending upon local code, an additional manual gas

shutoff, in a readily accessible area may be required and

located upstream from the appliance.

The bottom panel is removable if finishing material is not

installed. See Figure 9.2.

If

the finishing materials have been installed around the

appliance opening, proceed as follows:

1. Remove bottom glass shield.

2. Remove screws on left and right sides of component

heat shield and lift it out of the control cavity.

Figure 9.2 Bottom Glass Shield and Bottom Panel Location

CAUTION!

Risk of Overheating!

Component heat shield

MUST be installed before operating appliance. Electrical

components will be damaged.

C. Gas Service Access

BOTTOM PANEL SCREW LOCATIONS

BOTT

OM P

ANEL

BOTT

OM GLASS SHIELD