Propeller Owner’s Manual

147

INSTALLATION AND REMOVAL

61-00-47

Page 3-8

Rev. 17 Sep/20

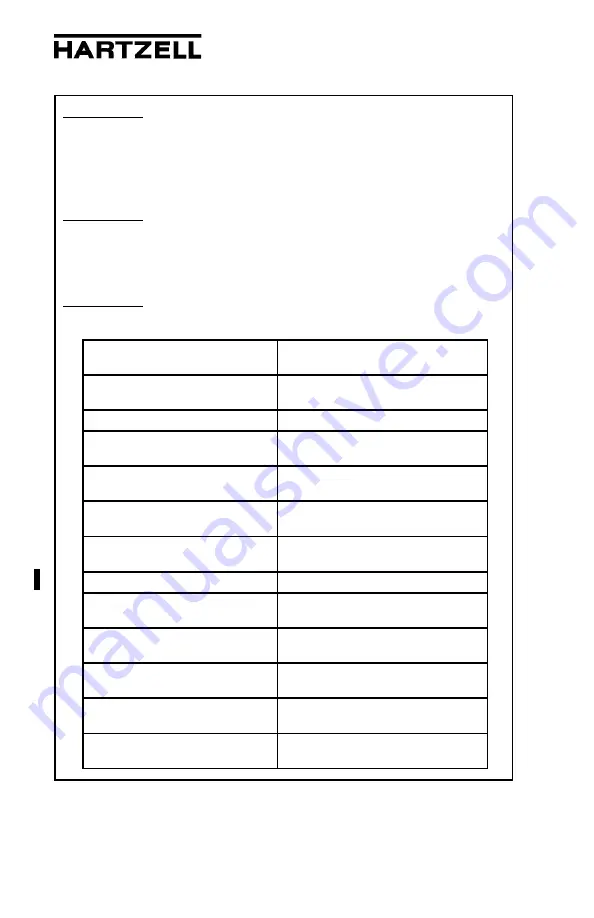

Torque Table

Table 3-2

CAUTION 1: FOR A PROPELLER THAT DOES NOT USE A

LUBRICATED (WET) TORQUE, THE MOUNTING

HARDWARE MUST BE CLEAN AND DRY TO

PREVENT EXCESSIVE PRELOAD OF THE

MOUNTING FLANGE.

CAUTION 2: TORQUE VALUES WITH “WET” NOTED AFTER

THEM ARE BASED ON LUBRICATED THREADS

WITH APPROVED ANTI-SEIZE COMPOUND

MIL-PRF-83483( ).

CAUTION 3: REFER TO FIGURE 3-2 FOR TORQUE READING

WHEN USING A TORQUE WRENCH ADAPTER.

A flange propeller mounting bolts

(except E5A-2)

100-105 Ft-Lbs (136-142 N•m) Wet

E5A-2 flange

propeller mounting nuts

120-130 Ft-Lbs (163-176 N•m) Wet

B flange propeller mounting bolts

100-105 Ft-Lbs (136-142 N•m) Wet

N flange propeller mounting bolts

except HC-E(4,5)N-(3,5)K(L)

100-105 Ft-Lbs (136-142 N•m) Wet

N flange propeller mounting nuts

HC-E(4,5)N-(3,5)K(L)

120-130 Ft-Lbs (163-176 N•m) Wet

P flange propeller mounting bolts

except HC-E5P-3

100-105 Ft-Lbs (136-142 N•m) Wet

HC-E5P-3

propeller mounting nuts

120-130 Ft-Lbs (163-176 N•m) Wet

W flange propeller mounting nuts

120-125 Ft-Lbs (163-170 N•m)

Adapter Plate to Hub bolts -

B-3384-4H

8-10 Ft-Lbs (10.8-13.5 N•m)

Slip Ring and adapter Plate Unit

to Hub screws - A-2070-7

8-10 Ft-Lbs (10.8-13.5 N•m)

Bulkhead to Adapter Plate

screws -B-3867-269

8-10 In-Lbs (0.9-1.1 N•m)

Pulley to Adapter Ring -

Pilatus fastener

48 In-Lbs (5.4 N•m)

Balance weight screws or bolts-

Aircraft quality #10-32 or AN-3( )

30-36 In-Lbs (3.4-4.0 N•m)