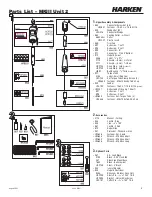

Parts List – MKIII Unit 2

August 2005

Unit 2 MKIII

37

1

- Upper Assembly & Components

• 854

Connector Screw Set (38)

HFG537 Fastener - 10-32 x

1

/

4

" 18-8 Slt Ov

• 855

Wedge Set (22)

HFG216

Connector Wedge

• 865

Locking Collar - w/Insert

865Collar Collar

HFG121 Plastic Insert

• 869

Trim Cap

• 897

Extrusion - 7' Luff

• 898

Extrusion - 2' Luff

• 899

Connector - 9"

• 911

Connector - 11.355" Bottom

• 912

Halyard Swivel

4456

Label -

3

/

8

" x 2

1

/

8

"

2119

Shackle - (8 mm)

5

/

16

" Twist

2117

Shackle - (8 mm)

5

/

16

" Bow

HCP723

Snap Ring - Large

(order 2)

HCP722

Snap Ring - Small

HBB7

Ball Bearing -

3

/

8

" Torlon

(order 92)

• 927

Torque Tube

4753

Label - Small Red Oval

HFG730

Set Torque Tube Clamp Screws (2)

HFS335 Fastener - M8x1.25x35 316 Sk Cap

• 939

Feeder

HFS192

Fastener - 10-32 x

3

/

8

" 18-8 Slt Ov

(order 2)

• HFG137

Extrusion Set (8 Long, 1 Short)

897

Extrusion - 7' Luff

898

Extrusion - 2' Luff

• HFG635

Fastener Set - Torque Tube (3)

HFS336

Fastener - M8x1.25x16 A4 Sk Cap

2

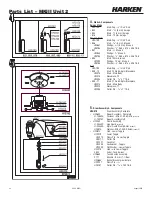

- Accessories

• 4115

Manual - Furling

• 833

Loctite - Blue

• 848

Line -

3

/

8

" x 100’

• 867

Loctite - 2 Red

• 872

Super Glue

• 947

Prefeeder - Phenolic w/Line

• HFG636

Fastener Set - Spare

• HFG643

Wrench - M5 Allen Short

• HFG644

Wrench - M6 Allen Short

• HFG646

Wrench - M8 Allen Long

3

- Optional Parts

• 267

Kit - Lead Block

019A

Block - 2.25" Hex Stbd

061

Stanchion Mount Base

168A

Block - Bullet Swivel

HCP168

Cleat - 4" Black

• 942

Isomat Adapter

• 945

Halyard Restrainer

945A

Sheave & SS Inner Race Only

HCP208

Clevis Pin -

5

/

16

" x 1.250" 18-8

HCP394

Bracket - Halyard Restrainer

HFS181

Cotter Pin -

3

/

32

" x .750" 18-8