38

Step 3.

Use a Moto-tool and a carbide cutter to make the

cylinder head and needle valve openings in the cowl.

Note:

For illustration purposes, we have shown an

MDS 1.48 glow engine mounted in the Edge 540.

If you use a different engine, it will be necessary to

make the appropriate template and mark the cowl to fit

the engine you have.

Step 4.

Mount the engine in the aircraft. Slide the cowl onto the

fuselage. Trial fit the cowl to the engine installed. Mount the

muffler and trial fit again. Make sure the engine is mounted so

the prop drive hub is 6

1

/

4

'' from the firewall. This should provide

an approximate 3/16'' clearance between the cowl and the

spinner backplate when mounted on the engine. Re-adjust the

cowl or engine if necessary to obtain the proper clearance.

Step 5.

Tape the cowl securely in position and check to make

sure it fits correctly. There should be ample clearance (1/8''

around the engine and muffler). Make sure the prop hub is

centered in the opening in the cowl.

Step 6.

There will be two-button head hold-down screws

located on either side of the cowl. With the cowl in position, the

top screw is located 1

1

/

2

'' from the edge of the cowl to the front,

1

/

2

'' down from the blue/yellow color line on the top of the cowl.

The bottom screw is located directly below the top screw, 3

1

/

4

'' at

a location 1

1

/

2

'' from the edge of the cowl and 3/8'' up from the

yellow/blue color line at the bottom of the cowl.

Step 7.

Once the mounting holes have been marked, drill the

holes on each side of the cowl using a 1/16'' drill bit. Be sure to

use masking tape to hold the cowl securely in position

Step 8.

Remove the cowling and enlarge the four holes in the

cowling just enough to fit the rubber grommets in place.

Note:

On some engines where the carburetor is not easily

accessible, a a fuel dot can be used. Hangar 9’s gold

anodize machined aluminum fuel dot with “T” coupler

(HAN115) is an excellent choice and should be

available at your local hobby shop.

Step 9.

Align the cowling on the fuselage and secure it with the

button head screws. Do not overtighten the screws by smashing

into the rubber grommets, as this will take away the vibration

isolation of the grommets.

Step 10.

Self-adhesive red trim tape is provided for trimming

the cowl.

Section 16: Attaching the Cowling

CONTINUED

Summary of Contents for EDGE 540

Page 52: ...52 ...

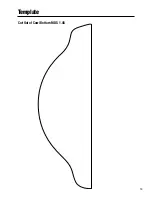

Page 53: ...53 Template Cut Out of Cowl Bottom MDS 1 48 ...

Page 54: ...54 ...

Page 55: ...55 ...

Page 56: ... 2000 Horizon Hobby Inc www horizonhobby com ...

Page 57: ...57 ...

Page 58: ...58 ...

Page 59: ...59 ...