17

e) close the valves of the pump and shut off (B). Verify that the gauge needle does not

move for about 5 minutes.

If the needle moves, there are air leaks in the system, then you must check all the

tightening and execution of flare at this point repeat the procedure from step c;

f)Disconnect the vacuum pump, (if you want to add refrigerant gas see the next

paragraph);

g) completely open the taps on 2 and 3 way valves (D);

h) Screw in the cap on the service outlet and valves (E);

i)after having tightened the plugs, make sure there are no gas leaks with the

appropriate detector.

Always protect hoses and cables to prevent their being damaged, as once damaged

can cause gas leaks(personal injury from frostbite).

5.8 Charge of the refrigerant gas

The product can be installed with refrigerant connection between internal and external

unit up to 20 m. The declared performances are referred to refrigerant connection

pipes of 5 m; different types of installation may lead to different values of

performance.

In case you are adding R134a gas in the circuit, will be needed:

- R134a refrigerant tank. In this case it is necessary a charge attack 1/2 UNF 20

threads per inch and corresponding seal;

- Electronic scale for refrigerant charging with sensitivity 10g.

- Connection pipes over 10 m need to increase the refrigerant(30g / m).

During installation:

a) Carry out the procedure of passage

Ā

a

ā

to the passage

Ā

f

ā

;

b) Connect the manometer on the low pressure service valve, and connect the

refrigerant cylinder to the center tap of the the manometer. Open the container of the

refrigerant then open the main valve cap pressure gauge and adjust the needle valve

until

you hear the coolant leak, and release the pin and close the valve of the the pipe;

c) Keep under control the weight of the refrigerant tank through the electronic scale;

d) Open the ball valve and to flow the refrigerant gradually;

e) After reaching the mass of gas to be loaded close the tap;

f) Remove the manometer and charging hose from the valve;

g) Fully open taps 2 and 3 way valves (D), turn the product in heat pump mode with

the detector and check for leaks of refrigerant;

h) Remove the container from the manifold and replace all the plugs (E).

Already installed:

a) Connect the manometer on the low pressure service valve, and connect the

refrigerant cylinder to the center tap of the the manometer. Open the container of the

refrigerant then open the main valve cap pressure gauge and adjust the needle valve

Summary of Contents for HP200S1

Page 5: ...5 3 Technical parameters ...

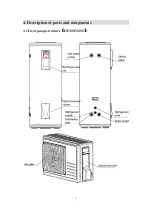

Page 6: ...6 4 Description of parts and components 4 1 Heat pump structure HP200 300S1 ...

Page 7: ...7 4 2 Exploded view 4 2 1 Exploded view tank unit ...

Page 13: ...13 5 2 Installation dimensions mm ...

Page 21: ...21 ...

Page 23: ...23 5 13 Wiring diagram ...

Page 24: ...24 6 Operation and functions Display 6 1 Description of the pictograms ...

Page 25: ...25 ...

Page 29: ...29 8 Faults and protection 8 1 Fault type ...

Page 30: ...30 8 2 Fault code identification method ...

Page 31: ...31 ...

Page 32: ...32 ...

Page 33: ...33 ...

Page 37: ...37 9 2 Remove the Control panel Use a screwdriver to remove the screws Remove it Remove it ...