15

WARNING! Before carrying out any installation check the following:

a) Use only copper tubes for air conditioners type (copper tubing for the refrigeration

and the conditioning) or copper pipes with proper insulation (at least 6 mm thick),

suitable for use with R134a;

b) Never use piping with a thickness less than 0.8 mm;

c) Provide a path of the pipes as short and simple as possible (maximum length 20 m

with 5 m of fall). Do not provide a path that may obstruct the access to the cap and

the removal of flange.

d) Protect the pipes and cables to avoid damage;

WARNING! The refrigerant lines, and fittings for connection must be insulated to

avoid dangerous burns, loss of performance and product malfunction. Ensure the

insulating sheath of the tubes through fastening clamps to prevent it from moving.

5.5 Connecting the tank unit

a) Shape the pipes according to the path;

b) Remove the threaded brass flare nuts(A) on the tank unit and store them

(check that no impurities are left);

c) Cut the pipe to the fixed length, with a pipe cutter, avoiding any deformation;

d) Remove burrs with pipe reamer avoiding to get impurities inside (keep down

Summary of Contents for HP200S1

Page 5: ...5 3 Technical parameters ...

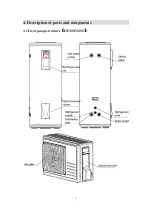

Page 6: ...6 4 Description of parts and components 4 1 Heat pump structure HP200 300S1 ...

Page 7: ...7 4 2 Exploded view 4 2 1 Exploded view tank unit ...

Page 13: ...13 5 2 Installation dimensions mm ...

Page 21: ...21 ...

Page 23: ...23 5 13 Wiring diagram ...

Page 24: ...24 6 Operation and functions Display 6 1 Description of the pictograms ...

Page 25: ...25 ...

Page 29: ...29 8 Faults and protection 8 1 Fault type ...

Page 30: ...30 8 2 Fault code identification method ...

Page 31: ...31 ...

Page 32: ...32 ...

Page 33: ...33 ...

Page 37: ...37 9 2 Remove the Control panel Use a screwdriver to remove the screws Remove it Remove it ...