14

5.3 Tools for the connection of refrigerant lines

a) Group manometer suitable for use with R134a, with charge and vacuum tubes;

b) Vacuum pump;

c) Torque wrenches for nominal diameter of 1/4 “and 3/8” sizes on both sides to

respond to the measures of the pipe unions;

d) Flaring clamp ø nominal 1/4 “and 3/8”, equipped with a terminal receiving

opening so that the projection of the copper tube can be adjusted from 0 to 0.5 mm

in the working folder ;

e) Pipe cutter;

f) Pipe reamer;

g) Leak Detector for R134a, a leak detector is used exclusively for HFC refrigerants.

It must have a high detection sensitivity.

5.4 Preparing of the refrigerating pipes

Summary of Contents for HP200S1

Page 5: ...5 3 Technical parameters ...

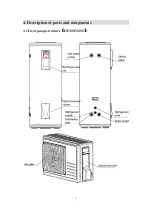

Page 6: ...6 4 Description of parts and components 4 1 Heat pump structure HP200 300S1 ...

Page 7: ...7 4 2 Exploded view 4 2 1 Exploded view tank unit ...

Page 13: ...13 5 2 Installation dimensions mm ...

Page 21: ...21 ...

Page 23: ...23 5 13 Wiring diagram ...

Page 24: ...24 6 Operation and functions Display 6 1 Description of the pictograms ...

Page 25: ...25 ...

Page 29: ...29 8 Faults and protection 8 1 Fault type ...

Page 30: ...30 8 2 Fault code identification method ...

Page 31: ...31 ...

Page 32: ...32 ...

Page 33: ...33 ...

Page 37: ...37 9 2 Remove the Control panel Use a screwdriver to remove the screws Remove it Remove it ...