15

TRT

TILTING ROTARY

TABLE

TRT

O

M

PERATOR’S

ANUAL

TILTING ROTARY

TABLE

96-5048 rev E

June 2002

2.4 T

HE

R

EMOTE

I

NPUT

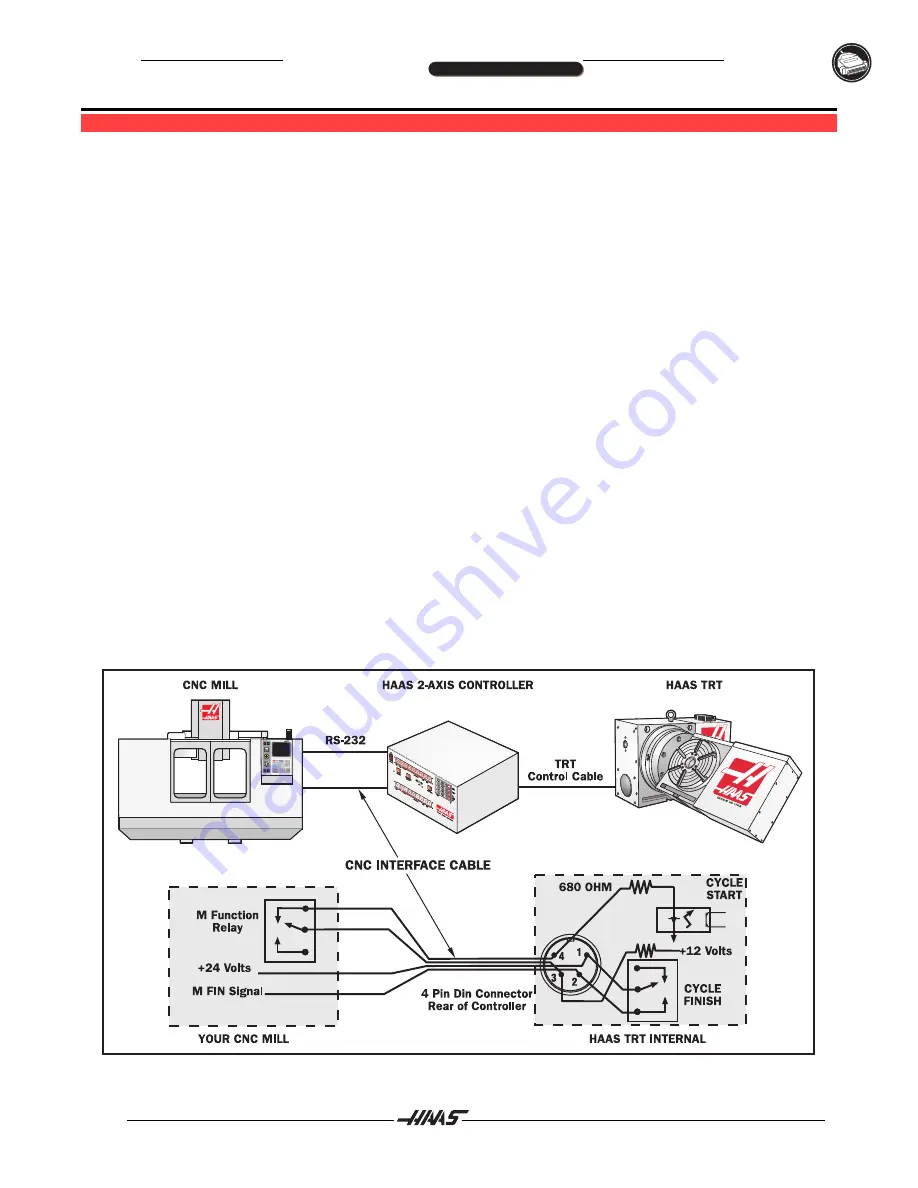

The CNC Interface Cable provides a basic method of communication between a non-Haas mill and Haas Servo

Control/Rotary Head. Since most CNC machine tools are equipped with spare M-codes, Semi-fourth axis

machining can be achieved by connecting one end of the CNC Interface Cable to any one of these spare relays

(switches), and the other to a Haas Servo Control unit. Indexing commands for the rotary unit are stored only in

the Servo Controls memory, and each pulse of the host machines relay triggers the control to index to its next

programmed position. After finishing the index, the Servo Control signals that it has finished and is ready for the

next pulse.

A remote socket is provided on the back panel of the control unit. The remote input consists of a

cycle start

line and a

cycle finish

line. To connect to the remote, you will need a connector supplied by HAAS (or one

obtained from a local source) that can be used to trigger the controller from any one of several sources. The

cable connector used is a male four-pin DIN connector. The Amphenol part number is 703-91-T-3300-1. The part

number of the panel receptacle in the control box is 703-91-T-3303-9.

Cycle Start

The figure shows the connector as viewed from the rear panel of the control unit. When pins 3 and 4 are

connected to each other for a minimum of 0.1 seconds, the control will index the head one cycle or step. To

index again, pins 3 and 4 must be opened for a minimum of 0.1 seconds. Under no circumstances should

power be applied to pins 3 and 4. A relay closure is the safest way to interface the control to your equipment.

When a

cycle start

is implemented, pin 3 supplies a positive 12 volts at 20 milliamps and pin 4 is connected to

the diode of an opto-isolator that grounds to chassis. Connecting pin 3 to pin 4 causes a current to flow through

the diode of the opto-isolator, triggering the control.

If the control is used around high frequency equipment such as electric welders or induction heaters, you will

need to use shielded wire to prevent false triggering by radiated EMI (electromagnetic interference). The shield

should be attached to earth ground.

A Typical CNC Interface.

SETTING UP TRT

Summary of Contents for TRT210

Page 2: ...Haas Technical Publications Manual_Archive_Safety_Pages Rev A June 6 2013...

Page 6: ...MILL WARNING DECALS Haas Technical Publications Manual_Archive_Safety_Pages Rev A June 6 2013...

Page 7: ...LATHE WARNING DECALS Haas Technical Publications Manual_Archive_Safety_Pages Rev A June 6 2013...