9

INSTALLATION INSTRUCTIONS

Temperature and Pressure-Relief Valve

DO NOT

plug the temperature and pressure-

relief valve or its discharge line.

DO NOT

remove

the relief valve. Make sure the relief valve is prop-

erly sized for the water heater. If the relief valve

continuously discharges water, call a qualified

service technician to correct the problem. Failure

to follow these instructions can result in property

damage, personal injury or death.

To protect from excessive pressure and/or temperature,

the manufacturer has installed a temperature and

pressure-relief valve that meetswith the requirements

of the Standard for Relief Valves and Automatic Gas

Shut-Off Devices for Hot Water Supply Systems, CSA

4.4, in Canada, and ANSI Z21.22, in the United

States. This relief valve has a maximum set pressure

that does not exceed the hydrostatic working pressure

of the water heater (150 psi = 1,035 kPa) and a BTU/h

rating equal to or greater than the input rating, as

shown on the water heater rating plate. It should never

be plugged or removed from the opening marked for it

on the water heater.

If this relief valve should needs to be replaced, use

only a new temperature and pressure-relief valve.

Never install an old or existing relief valve, as it

may be damaged or inadequate for the working

requirements of the new water heater. This new relief

valve must meet with all local codes or, at a

minimum, the requirements listed above. Never

install any other type of valves between the relief

valve and the water heater.

A discharge line must be installed into the relief

valve.

The discharge line:

• Must not be smaller than the outlet pipe size of

the relief valve.

• Must not terminate less than six (6) inches (15.2

cm) and not more than twelve (12) inches (30.5

cm) above a floor drain.

• Must not be restricted in any way. Do not thread,

cap or in any way restrict the end of this outlet.

• Must be of a material capable of withstanding

210˚F (99˚C) without distortion.

• Must be installed to allow complete drainage of

the relief valve and discharge line.

• Must terminate at an adequate free-flowing drain.

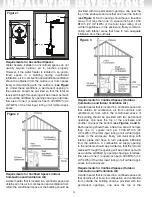

Pressure Build-up in a Water System

When the water heater operates, the heated water

expands creating a pressure build-up. This is a

natural function and is one of the reasons for

installing a temperature and pressure-relief valve. If

the cold water supply line has a built-in water meter,

check valve or pressure-reducing valve, a suitable

expansion tank must be installed to prevent pressure

build-up or water hammer effect. Otherwise, the

warranty will be void

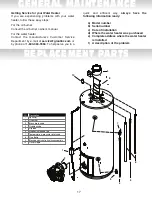

(see Figure 10)

. An indication

of pressure build-up is frequent discharges of water

from the relief valve. If the relief valve discharges

water on a continual basis, it may indicate a

malfunction of the relief valve and a qualified service

technician must be called to have the system

checked and the problem corrected.

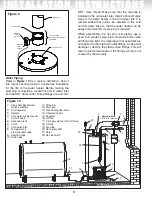

Filling the Water Heater

NEVER

operate the water heater unless it is

completely filled with water. Failure to follow this

instruction can result in premature failure of the

water heater that is not covered by the warranty.

Check that all of the water piping connections have

been made. To fill the water heater:

1) Make sure that the water heater drain valve is

closed by inserting a flat head screwdriver into the

slot on the head of the drain valve and turning the

knob clockwise .

2) Open the cold water supply manual shut-off valve.

This valve must remain open, as long as the water

heater is in use. Never operate the water heater

with the cold water supply manual shut-off valve

closed.

3) To make sure the water heater is completely filled

with water, open hot water faucets to let the air out

of the water heater and plumbing system. Leave

the faucets open until a constant flow of water is

obtained.

4) Check all of the plumbing connections to make

sure there are no leaks.

Oil Supply

The entire fuel system should be installed in accor-

dance with all local codes or, in the absence of such

codes, the latest edition of the CAN/CSA B139,

Installation for Oil Burning Equipment, in Canada,

and/or the latest edition of the Installation of Oil

Burning Equipment, NFPA 31, in the United States.

Use only approved fuel oil tanks, piping, fittings, oil

filters and any other fuel handling components.

Install the oil filter as close to the burner as possible.

For further details of the oil supply tank and piping

requirements, please refer to the instructions and

WARNING

WARNING