INSTALLATION INSTRUCTIONS

Louvers and Grilles

In calculating free area for ventilation and combus-

tion air supply openings, consideration must be

given to the blocking effect of louvers, grilles or

screens protecting the openings. Screens must not

be smaller than 1/4 inch (6.4 mm) mesh. If the free

area through a particular design of louver or grille is

known, it should be used in calculating the size of

opening required to provide the free area specified.

If the design and free area is not known, it may be

assumed that wood louvers and grilles will allow 20-

25% free area and metal louvers and grilles will allow

60-75% free area. Louvers and grilles must be

installed in the open position or interconnected with

the water heater so that they are opened automati-

cally during water heater operation.

Corrosive Atmospheres

If this water heater is to be installed in a beauty shop,

barber shop, photo processing lab, dry cleaning

establishment, a building with an indoor pool or near

a chemical storage area, it is imperative that the

combustion and ventilation air be drawn from outside

these areas. These particular environments contain

products such as aerosol sprays, detergents, bleach-

es, cleaning solvents, refrigerants, and other volatile

compounds that, in addition to being highly flamma-

ble, become highly corrosive acid compounds when

burned. Exposure to such compounds can be

hazardous and lead to premature product failure.

Should the water heater fail, due to exposure to

such a corrosive atmosphere, the warranty is

void.

Venting

When installing the venting system, make sure to

follow all local codes or, in the absence of such

codes, the latest edition of the CAN/CSA B139,

Installation for Oil Burning Equipment, in Canada,

and/or the latest edition of Standard for the

Installation of Oil Burning Equipment, NFPA 31, in

the United States. Never operate the water heater

unless it is properly ventilated to the outdoors and

has adequate air supply for proper operation. Failure

to properly install the venting system could result in

property damage, personal injury or death.

Chimney Requirements

If this water heater is operated with a burner designed

for natural draft venting, it must be connected to a ver-

tical chimney. The chimney must be properly con-

structed and sized, clean and free of soot,

creosote and obstructions, able to generate sufficient

draft to evacuate the products of combustion

outdoors and be lined with a tile or metal liner. Inspect

the chimney and make any repairs necessary before

installing the water heater.

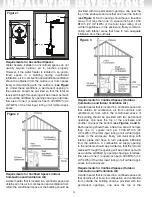

To prevent downdrafts, the chimney flue should

extend at least three (3) feet (1 m) above the highest

point at which the chimney comes in contact with

the roof and not less than two (2) feet (0.6 m) above

the highest roof surface or structure within ten

(10) feet (3 m) of the chimney on a horizontal plane

perpendicular to the chimney. Not more than four

(4) inches (100 mm) of chimney flue above the top of

the chimney cap should be considered in computing

this height

(see Figure 8)

. Increase the cross-sectional

area and height of the chimney at least 4% per 1,000

feet (305 m) above sea level.

Failure to properly inspect and repair the chimney

could result in property damage, personal injury or

death.

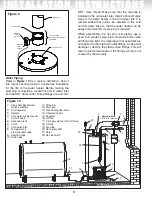

Flue Piping

Before installing the flue piping, make sure that the

venting system layout has been properly planned.

Make sure that the flue baffle has been installed in the

flue tube. If the baffle is not present, immediately con-

tact the dealer where the water heater was purchased.

NEVER

operate the water heater without the flue baf-

fle installed. Verify that the location of the water heater

and the venting system respects all clearances from

combustible materials (

see Figure 1

).

The length of flue pipe to vent this water heater should

be as short as possible with horizontal runs sloping

upward towards the chimney at a rate of at least

one-quarter (1/4) inch per foot (21 mm/m). Long hori-

zontal runs of flue pipe, sharp turns and other con-

struction features that could create excessive resist-

ance to the flow of flue gas should be avoided. The

flue pipe must not be smaller in cross sectional area

that the flue collar on the water heater. The flue pipe

must not pass through any floor or ceiling, but may

pass through a wall where suitable fire protection

provisions have been installed. The flue pipe should

connect to the chimney such that it extends into, and

terminates flush with, the inside surface of the

chimney liner. The joint between the flue pipe and the

chimney liner should be sealed and all unused

chimney opening should be closed.

6

DANGER

WARNING