INSTALLATION INSTRUCTIONS

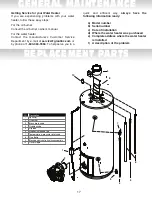

Draft Regulator (Barometric Damper Control)

This device is used for conventional chimney venting

only. It automatically maintains a constant negative

pressure in the chimney to obtain maximum

efficiency. It ensures that proper pressures are not

exceeded. If the chimney does not develop sufficient

draft, the draft control cannot function properly.

When installed, the draft regulator should be located

in the same room or enclosure as the water heater

and not interfere with the supply of combustion air to

the oil burner.

The water heater must be connected to a flue

having sufficient draft at all times to ensure safe

and proper operation of the appliance. The flue

outlet pressure (measured between the water

heater and draft regulator) should be set to -0.02

inches w.c. Failure to provide sufficient draft for

this water heater could result in property damage,

personal injury or death.

Flue Collar/Blocked Vent Switch Assembly

(Installation and Operation)

This water heater has been shipped from the factory

with a flue collar/blocked vent switch assembly. This

switch is designed to detect flue gas spillage due

to a blocked flue, continuous down drafting or

inadequate draft condition.

All wiring must be installed by a qualified installer

in accordance with all local codes or, in the

absence of such codes, the latest edition of the

CSA C22.1, Canadian Electrical Code, in

Canada, and/or the latest edition of the National

Electrical Code, NFPA 70, in the United States.

Before installing the switch, remember to DIS-

CONNECT THE POWER SUPPLY to the water

heater. Failure to follow these instructions can result

in property damage, personal injury or death.

Installation:

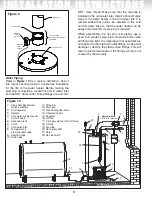

1) Install the pre-assembled flue collar/blocked vent

switch assembly over the flue outlet on the water

heater

(see Figure 9)

.

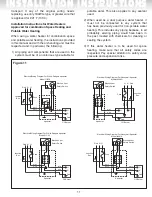

2) Wire the switch to the aquastat on the water

heater

(see wiring diagram in Figure 11)

.

3) Install the vent pipe onto the flue collar and

secure it using sheet metal screws (not supplied).

Operation:

With the switch wired to the aquastat circuit, it will

shut down the burner once it senses the spillage of

hot flue gas. The switch will not allow the burner to

restart until it has been manually reset. In order to

manually reset the switch:

1) Wait for the vent pipe to cool down.

2) Insert the end of a pencil or square head screw

driver into the opening for the reset (

see Figure 9

)

and depress the red reset button.

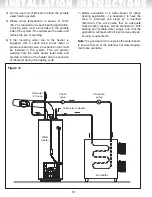

Optional Sidewall Venting (Power Vent)

This water heater is approved in Canada for use with

the Tjerlund SS1C side shot power venter and in the

United States with the Tjerlund SS1 side shot power

venter. This power vent kit is available through major

HVAC supply companies. Technical support is

offered by Tjerlund, not by the manufacturer of this

water heater.

When the installation is complete, visually inspect

the venting system to make sure that all joints are

properly connected and all instructions have been

followed. Failure to properly install the venting

system could result in property damage, personal

injury or death.

7

WARNING

WARNING

Figure 8

WARNING