10

INSTALLATION INSTRUCTIONS

illustrations that come with the burner. If the water

heater is installed using a float valve between the oil

supply tank and the burner, and the supply tank is

over nine (9)-gallon capacity, a valve operated by a

fusible link shall be installed in the fuel line adjacent

to and upstream from the float valve.

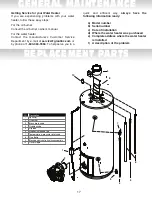

Oil Burner Installation

The installation of the oil burner must be per-

formed by a qualified Oil Burner Technician.

Before installing the oil burner, check the align-

ment between the burner and the combustion

chamber. It is possible for the combustion cham-

ber to shift if it is subjected to rough handling dur-

ing transit. The end cone of the air tube must be

centered to the accommodating passage provided

in the design of the combustion chamber. Adjust

as necessary. Failure to follow these instructions

can result in property damage, personal injury or

death.

The installation of the oil burner must be in accor-

dance with all local codes or, in the absence of such

codes, the latest edition of the CAN/CSA B139,

Installation for Oil Burning Equipment, in Canada,

and/or the latest edition of the standard for Installation

of Oil Burning Equipment, NFPA 31 in the United

States.

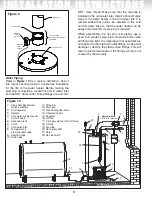

Oil Filter

All fuel systems should include an oil filter between

the fuel oil storage tank and the oil burner. When

using an oil burner nozzle smaller than 0.75, install

an additional 10 micron or better filter as close as

possible to the oil burner.

Oil Burner Nozzles

The OG32 water heater is certified for multiple firing

rates, ranging from 82,000 to 103,000 BTU/h. The

OG50 models are certified for multiple firing rates,

ranging from 97,000 to input 117,000 BTU/h. Refer

to the water heater rating plate or

Table 1

to deter-

mine the proper burner settings.

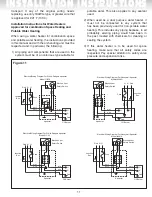

Wiring

This water heater uses an external electrical

source for power. It must be electrically grounded

in accordance with all local codes or, in the

absence of such codes, the latest edition of the

CSA C22.1 Canadian Electrical Code, in Canada,

and/or the latest edition of the National Electrical

Code, NFPA 70, in the United States. Failure to

properly ground this water heater can result in

property damage, personal injury or death.

This water heater is factory wired and requires mini-

mal field wiring. The water heater should be wired to

a separate and dedicated circuit in the main electri-

cal panel. Although a suitably located circuit breaker

can be used as a service switch, a separate service

switch is advisable. The service switch is necessary

if reaching the circuit breaker involves becoming

close to the water heater or if the water heater is

located between the circuit breaker and the means

of entry to the furnace room. The water heater switch

(service switch) should be clearly marked, installed

in an easily accessible area between the water

heater and furnace room entry, and be located in such

a manner to reduce the likelihood that it would be mis-

taken as a light switch or similar device (

see Figure 10

).

The power requirement is 120VAC, 60Hz.

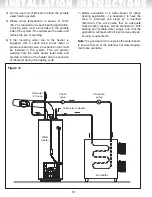

Before lighting your water heater, check that all

of the wires have been installed correctly

(see

Figure 11)

. Make sure that none of the wires are

grounded, have split, or are broken. Verify that all

wiring connections are properly secured, as there is

a possibility that they have become loose during

Table 1

WARNING

OIL INPUT

Water Heater

Blast Tube

Model No.

Burner Model No. Designation

Insertion

Nozzle, Firing Rate @ psi

4

3/4

’’

0.60 - 70°A 82,000 BTU @ 100 psi

4

3/4

’’

0.65 - 70°A 90,000 BTU @ 100 psi

4

3/4

’’

0.75 - 70°A103,000 BTU @ 100 psi

4

3/4

’’

0.70 - 70°A 97,000 BTU @ 100 psi

4

3/4

’’

0.75 - 70°A103,000 BTU @ 100 psi

4

3/4

’’

0.85 - 70°A117,000 BTU @ 100 psi

OG32

Beckett AF

OG50

Beckett AF

WARNING