15

GENERAL MAINTENANCE

Housekeeping

DO NOT

store or use gasoline or any other flam-

mable vapours or liquids around the water heater.

DO NOT

put or store any objects on the top of the

water heater. Failure to follow these instructions

can result in property damage, personal injury or

death.

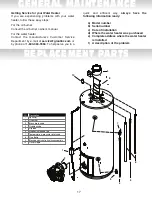

Annual Service by a Contractor

The combustion chamber is fragile. Use care when

inspecting and cleaning this area. The heat exchang-

er flue passage and baffle should be inspected peri-

odically and cleaned if necessary. A wire brush can

be used to loosen dirt and debris on the inside sur-

face of the flue passage and baffle. Clean out all

accumulated dirt and soot with an industrial vacuum

cleaner, paying close attention to the combustion

chamber area.

Routine Maintenance by the Home Owner

Keep the area around the water heater clean and

free of dust, lint and dirt. Make sure that all of the

minimum clearances to combustible materials are

being maintained. On a regular basis, you should

inspect the general conditions of the water heater,

watching for signs of oil leaks in the vicinity of the oil

burner and soot forming on any external part of the

water heater or joints of the vent pipes, etc. If any of

these conditions are present, please advise your

service or installation contractor. The water heater

should be serviced on an annual basis by a qualified

service technician.

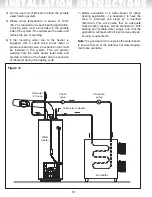

Oil Burner Air adjustment

At the time of installation, and at least at each annual

cleaning or inspection, a test for smoke density and

carbon monoxyde (CO) must be performed. Drill a

test port in the venting between the water heater flue

outlet and the draft regulator (barometric damper). It

is essential for the proper operation of the water

heater that this adjustment is performed with the use

of combustion instruments, as a visual inspection is

not sufficient. Oil-fired water heaters tend to run with

shorter operating cycles and it is therefore important

for the burner to be adjusted to provide a good flame.

A lack of air causes “sooty” or “soft” flames, resulting

in soot build-up throughout the heat exchanger pas-

sages. Excess combustion air causes a bright roar-

ing fire and high stack temperatures resulting in poor

fuel efficiency.

After the burner has been firing for 10-15 minutes,

take a smoke sample with a Bacharach smoke

sampler or other approved device. Then, take a sam-

ple of the flue gases and test for CO using a combus-

tion analyser. The smoke spot should not exceed

“Trace” on the Bacharach Scale. The water heater

operates most efficiently with a “Trace” smoke spot.

For complete details on adjusting the air, please con-

sult the oil burner instruction manual

provided with the burner.

Burner electrode

Correct positioning of the electrode tips with respect

to each other, to the fuel oil nozzle and to the rest of

the burners is essential for smooth light ups and

proper operation. Refer to the oil burner instructions

shipped with the burner for electrode specifications.

Burner primary (safety) control

The oil burner is equipped with a primary combus-

tion control, sometimes referred to as the burner

relay or burner protector relay, which uses a light

sensing device (cad cell) located in the burner

housing, to monitor and control combustion. Over

time, dust or combustion residuals can build up on

the lens of the cad cell impairing its response to

the flame. The cad cell should be checked for

cleanliness and proper alignment if the primary

control frequently shuts down combustion.

Shutting Down the Water Heater

Always keep the oil supply manual shut-off valve-

closed if the burner is shut down for an extended

period of time

Set the aquastat to the lowest possible setting.

Turn off all of the electrical power to the water heater.

Condensation

As moisture from the products of combustion comes

into contact with the cold surface of the inner tank, it

may condense. This situation will usually occur:

1) When the water heater is filled with cold water for

the first time.

2) If the water heater has been undersized.

3) When large amounts of hot water are drawn from

the water heater in a short period of time and the

refill water is very cold.

Due to the high-efficiency rating of this oil-fired water

heater, it may produce more condensation than older

models. This condition is not uncommon and must

never be misinterpreted as a leaking tank. It will

disappear once the water becomes heated.

WARNING

WARNING