PRINTED IN U.S.A.

59

50960066/AP0813

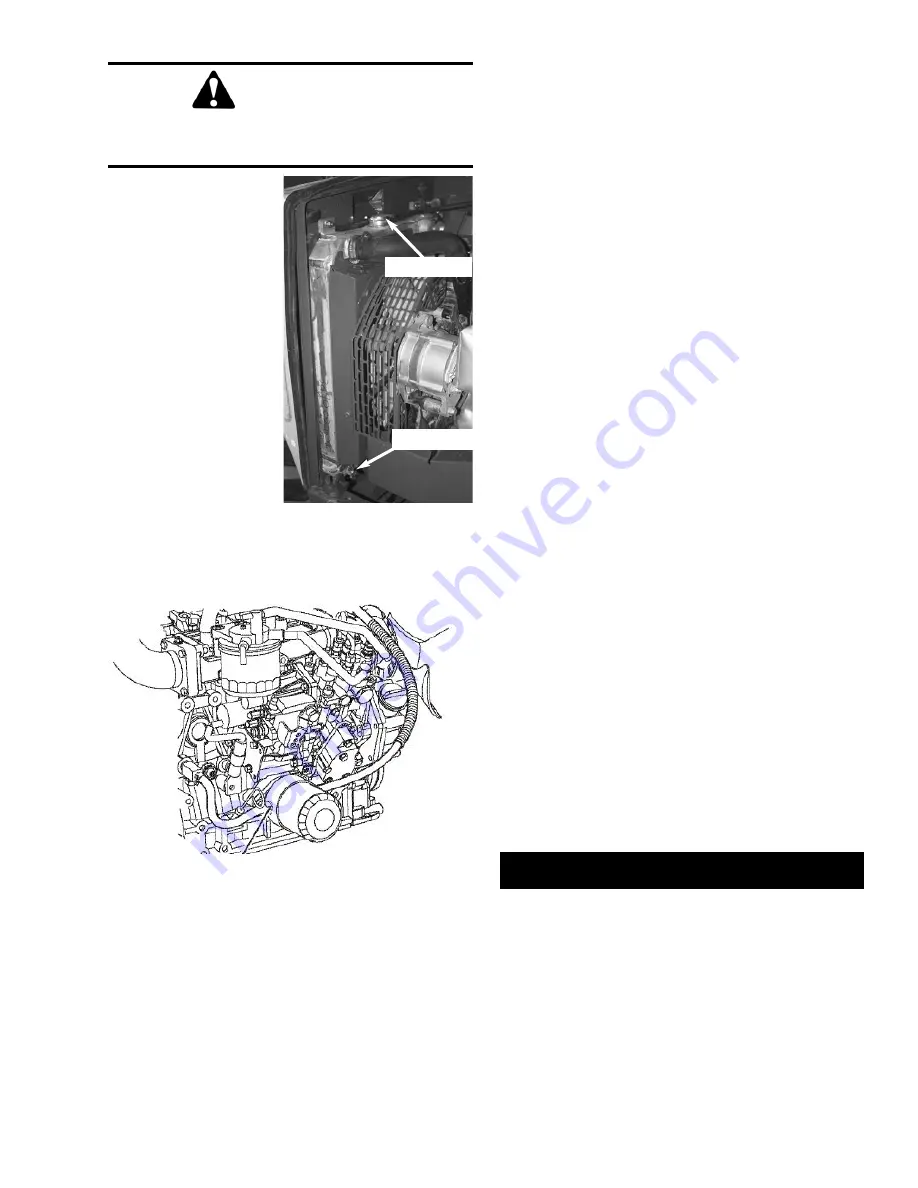

1. Remove the engine

belly pan.

2. Loosen the radiator

cap to its stop. This

will release any sys-

tem pressure.

Remove the cap

when all pressure is

bled off.

3. Attach a 3/8” hose to

the drain cock and

route it through the

belly pan opening to

a collection contain-

er positioned below

the radiator.

4. Loosen the radiator drain cock to drain the radia-

tor.

5. Remove the coolant hose from the engine oil cool-

er to allow coolant to drain from the engine block.

6. When all coolant is drained, flush the system with

clean fresh water to remove any rust, scale and

contaminants. Allow the radiator and engine block

to drain completely.

7. Replace all drain plugs and tighten the radiator

drain cock. Clean the cooling fins in the radiator

with compressed air or water pressure.

IMPORTANT:

Fill the cooling system with a low-

silicate ethylene glycol based coolant mixed with

quality water and supplemental coolant additives

(SCAs) suitable for heavy-duty diesel engines.

See the engine manual for additional information.

8. Pour the coolant slowly into the radiator until the

coolant is at the bottom of the filler neck. Remove

the cap of the expansion tank and add coolant to

the full mark.

9. Inspect the radiator cap seal before installing it.

Replace it if it appears to be damaged.

10. Run the engine until it reaches operating tempera-

ture. Check the coolant level in the expansion tank.

Add coolant to the expansion tank to bring the

level up to the full mark.

NOTE:

Check the engine temperature gauge

every minute or two after coolant has been

changed. Air pockets can form and it may be nec-

essary to refill the cooling system after a short

period of use, as the air bleeds out of the system.

CHECKING ALTERNATOR AND FAN

BELT CONDITION

Refer to the engine manual for proper belt tension

adjustment and replacement procedures. If the belt

shows wear or cuts, or cracks, it should be replaced.

Order replacement belt from your engine dealer.

CHECKING EXHAUST SYSTEM

Examine the muffler and tail pipe for possible holes.

Re-tighten any loose clamps and make sure the mani-

fold outlet gasket is not leaking. Examine the exhaust

insulating blanket for holes or tears. To prevent exces-

sive heat build up in the engine compartment the insu-

lating blanket should be replaced when it is damaged.

IMPORTANT:

To prevent damaging the insulating

blanket, do not spray it with high pressure water

blast when cleaning the engine.

Perform all other service requirements up to this point,

as well as the following.

CHECKING HYDRAULIC SYSTEM

RELIEF PRESSURES

Pressure settings for relief valves are pre-set at the fac-

tory. A test port is provided under the engine cover.

Service Every 2000 Hours or Two Years

Oil Cooler

Coolant Hose

WARNING

Remove the radiator cap only when the engine

is cool, or painful burns could result.

Radiator Cap

Drain Cock

Summary of Contents for RS5-19

Page 8: ...50960066 AP0813 6 PRINTED IN U S A INTENTIONALLY BLANK To be removed as Dealer s file copy...

Page 69: ...PRINTED IN U S A 67 50960066 AP0813 Date Hours Service Procedure MAINTENANCE LOG...

Page 70: ...50960066 AP0813 68 PRINTED IN U S A Date Hours Service Procedure MAINTENANCE LOG...

Page 73: ...PRINTED IN U S A 71 50960066 AP0813 Electrical Schematic...

Page 74: ...50960066 AP0813 72 PRINTED IN U S A Hydraulic Schematic...