SR Meterbox Assembly

Page 103

05/09

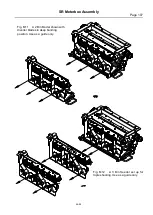

SR Meterbox Assembly

The SR Meterbox assembly creates the

base

structure

to

enable

various

configurations in sowing requirements to be

achieved. The base structure allows for a

maximum of 6 primary delivery tubes. It can

also be supplied as a 4 outlet meterbox as

standard from the factory.

SR Meterbox Features

The SR Meterbox has been fitted with

adjustable diverter blades to allow for

partial or total diversion of material from

one meterwheel to an adjacent primary

delivery tube (refer fig. M2).

Fig. M2 Diverter blades set to one side.

Removable

clear

window

assemblies

located on the rear face of the meterbox

allow access to the meterwheels while

product is in the bin. The windows will also

give visual confirmation of the diverter

blades orientation.

The hatch frame assembly is used to hold

the hatch assembly in place at the bottom

of the meterbox. The hatch frame can be

opened when product is in the bin by

rotating the hatch frame handle downwards

and towards the rear of the seeder. The

securing hooks can then be lifted from the

catch pins, allowing the hatch to rotate

forwards.

The hatch frame can be rotated forward

and upwards to lock into a near horizontal

position to give maximum access to the

underside of the meterbox.

Fig. M3 Hatch frame being opened.

Note: A yellow safety catch situated forward and to

the right hand side of each meterbox should be

engaged if someone is working under the machine.

Engaging the safety catch prevents the

hatch handle from being rotated, which inturn

releases the hatch from its fully open position

(refer fig. M4).

Fig. M4 Safety Catch Operation.

The hatch frame will generally hang

vertically

down

when

calibrating

the

meterbox, and locked horizontally when

emptying material from the bin.

To gain maximum ground to under

meterbox clearance, it may be necessary to