Meterbox Assembly - General

Page

109

12/09

Fig. M16 Grub screws on metershaft bearing.

4.

Undo and remove the 3 button head

screws that are used to retain the

plastic nose assembly to the driving

end of the metershaft.

5.

Slide

the

metershaft

and

nose

assembly out away from the handle

end. It may be necessary to use a long

drive pin punch through the hole in the

handle

to

start

the

metershaft

movement.

Fig. M17 Removing screws from drive end.

6.

As the metershaft moves out and away

from the housing the meterwheels can

be removed one at a time.

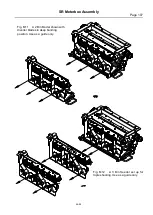

Fig. M18 Withdrawing metershaft from housing.

Assembly is a reversal of this operation.

Before

rebuilding

the

metershaft

assembly check that the bearings turn

freely. The bearing in the nose assembly will

be firm to turn but should rotate and feel

smooth in its operation. If excessive force is

required, or a bearing feels rough when

rotating replace bearing before re-assembly.

Clean hexagonal metershaft of product build

up to allow the meterwheels free movement

along the shaft.

Check that the meterwheels are in good

condition & not worn before re-assembling.

Check that the vertical spacers attached to

the housing are not excessively worn and

are still functional. The vertical spacers are

used to retain the meterwheels in position.

Replace individual units if required.

Fig.M19 Checking vertical spacer for wear.

Check that the drive pin on the end of the

shaft is in good condition.

Fig.M20 Drive pin in end of metershaft.